INSTALLING AND SECURING UNIT

TO WALL SLEEVE

Before installing and securing the unit to the wall sleeve, make sure

that the proper grille kit is installed. Due to the temperatures of the

combustion products released from the gas vent, DynaPack gas package

units require the use of an aluminum grille kit (see ACCESSORIES on

page 7).

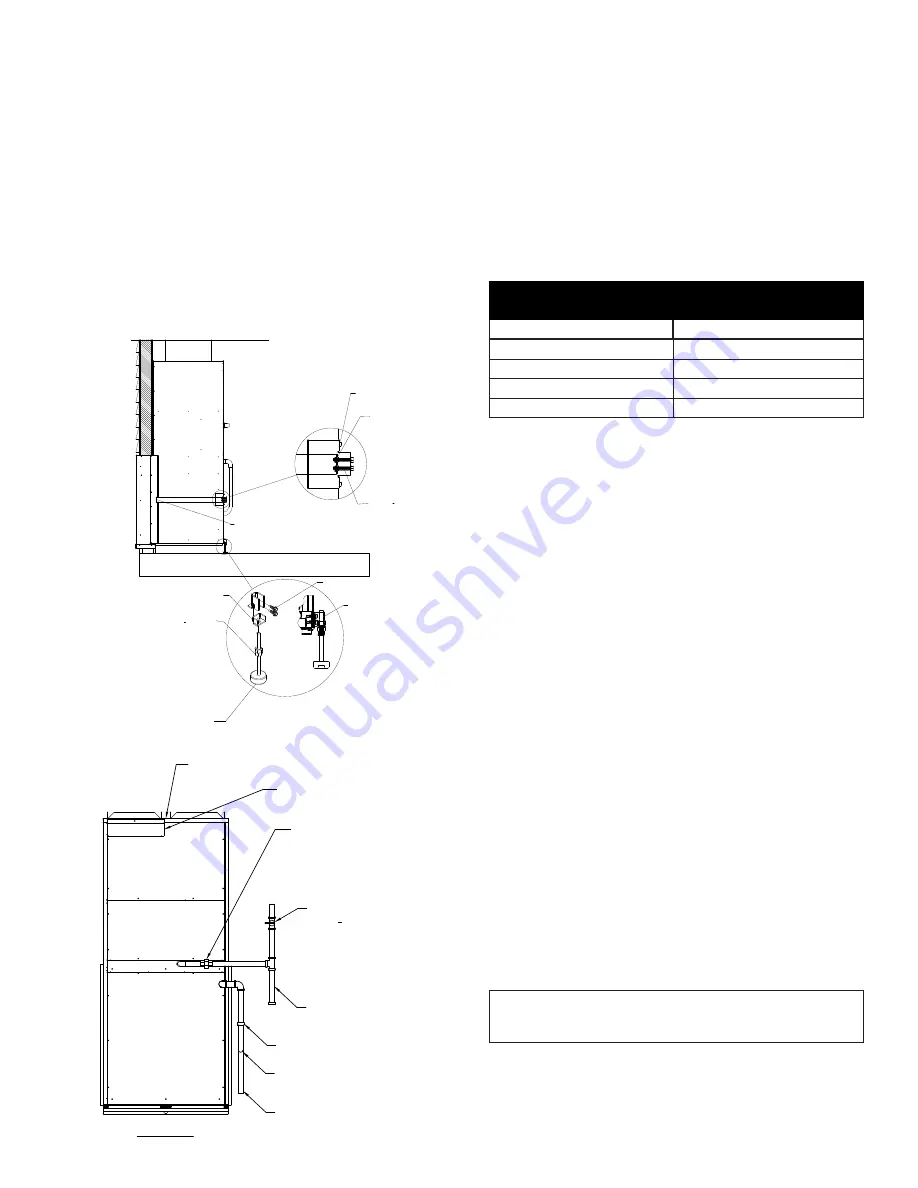

1.

Double check the installation of the wall sleeve to make sure it is securely

attached to the wall opening. Inspect the wall sleeve drain for proper

installation if an inside drain is being used.

2.

Examine the gaskets on the wall sleeve to make sure there is a continuous

seal between the wall sleeve and the unit.

3.

Place DynaPack unit onto the wall sleeve. Lift the unit 3/4" and place over

the wall sleeve base (see Figure 3). A PALLET JACK works well for this.

Temporarily block the unit up and install front leveling bracket (see Figure

3). Adjust leveling legs to level.

4.

Use the two retaining straps to secure the unit to the wall sleeve (see Figure

3). Verify that the gaskets of the wall sleeve make a complete seal to the

unit paying particular attention to top and bottom corners of the unit to

sleeve seal. Caulk if needed.

DUCT WORK

The duct work for the dwelling should be designed for the lowest

possible static pressure to reduce energy usage and noise. Table 2 lists

the approximate cfm delivery of the units on each of the indoor blower

speeds. Table 4 lists the recommended heating and cooling speeds

with its approximate cfm delivery. Use both tables to properly design

the duct system for both heating and cooling cfm.

AIR FILTER

The Dynapack unit is equipped with a permanent, cleanable air filter.

This filter can be used if the unit is installed so that the filter is accessible

to the homeowner. The permanent filter installed inside the unit must

be removed and discarded if a disposable filter is installed in the return

air duct. See Table 3 for the minimum filter area required for the

Dynapack unit based on unit capacity. It is recommended that air filters

be cleaned or replaced monthly to keep the cooling coil and interior duct

surfaces clean and able to operate most efficiently. Optional MERV 13

filters are available.

MINIMUM REQUIRED SURFACE AREA FOR

DISPOSABLE FILTERS

MODEL NUMBER

FILTER AREA

DYPA12

288 square inches

DYPA18

288 square inches

DYPA24

480 square inches

DYPA30 & DYPA36

480 square inches

TABLE 3

CONDENSATE DRAIN

The Dynapack unit and wall sleeve each have there own drain. The unit

drain is for the condensate developed by the evaporator coil. It needs

to be trapped and routed to the building drain system. Use ¾” pvc pipe

and fittings (field supplied).

The wall sleeve is equipped with a drain pan that collects rain water

entering the wall sleeve and the unit condenser coil area. At the time

of installation of the wall sleeve, this drain can be directed directly out-

side or turned inside and routed to the building drain system. If the

wall sleeve drain is routed to the building sewer system then it must be

trapped to prevent sewer gasses from escaping.

ELECTRICAL CONNECTIONS

The Dynapack unit is approved using copper conductors only. See the

unit data plate for unit minimum circuit ampacity. Size the wire based

on the unit circuit ampacity, type of wire used, and method of wiring, in

conduit or open. If the electrical supply is 208 volt, then do not exceed

3% voltage drop based on the length of wire run. See the National

Electrical Code or the Canadian Electrical Code for more information.

The typical electrical supply is two phase wires where voltage measured

is 208-230 volts phase to phase. An additional wire for unit grounding

is required. See the unit data plate for the maximum fuse or circuit

breaker size. It is recommended that time delay fuses or a two pole

HACR breaker be used in order to prevent nuisance trips.

Alternately, the Dynapack unit may be wired with one phase wire

where the voltage measured is 208-230 volts phase to neutral. In this

case, the phase wire should be connected to L1 on the contactor. An

additional wire for unit grounding is required.

On 208 volt systems the transformer wiring needs to be changed. Swap

the red transformer wire for the orange wire for 208 volt operation.

A disconnect should be installed next to the unit so the electrical power

can be turned off for servicing or maintenance.

GAS SUPPLY

All Dynapack units are built to operate on natural gas. The unit must

be converted using the manufacturers conversion kit in order to operate

on LP gas.

WARNING!

Any conversion of a natural gas unit to liquefied petroleum (LP) gas must be

done by qualified personnel using a conversion kit available from the manufacturer, following

the instructions in the conversion kit, If done improperly, over firing of the burners and improper

burner operation can result. This can create carbon monoxide which could cause asphyxiation.

Minimum gas supply pressure for purposes of input adjustment:

Minimum

Maximum

Natural Gas

5" W.C. *

10" W.C.

Liquefied Petroleum (LP) Gas

11" W.C.

13" W.C.

*Water Column

3

#10-24 X 1

1

2

MACHINE SCREW

LEG LEVELER

38-16 HEX NUT

THE LEVELER BRACKET INSTALLS

INTO UNIT BRACKET AND IS HELD

IN PLACE BY THE UNIT WEIGHT

#12 X .75" DRILL SCREWS

(2 PLACES)

LOCATE BRACKET BY INSTALLING

THE TAB UNDER THE UNIT BASE

AND ABOVE THE BASE RAIL.

TINNERMAN CLIP

ATTACH BRACKET TO UNIT

WITH (2) #10 X 1/2" DRILL SCREWS

(2 ON EACH BRACKET)

ENGAGE FLANGE ON WALL SLEEVE

WITH FLANGE ON STRAP. TIGHTEN

MACHINE SCREWS UNTIL BRACKET

CAN BE SECURED TO UNIT WITH

DRILL SCREWS.

RETURN

SUPPLY

ACCESS PANEL

TO

CONTROLS

ACCESS PANEL

TO GAS VALVE

AND BURNERS

ACCESS PANEL

TO COMPRESSOR

AND OUTDOOR FAN

DRIP LEG (FIELD SUPPLIED)

MANUAL SHUTOFF VALVE

WITH

1

8

"NPT PLUGGED TAPPING,

ACCESSIBLE FOR TEST GAUGE

CONNECTION (FIELD SUPPLIED)

CONDENSATE DRAIN

GROUND JOINT UNION

(FIELD SUPPLIED)

FILTER DOOR

TRAP

ROUTE TO BUILDING DRAIN

ELECTRICAL POWER ENTRANCE

FRONT VIEW

Figure 4

Figure 3