(April, 2013)

DRH Series GEN1 Ultrasonic Humidifi er Installation, Operation & Maintenance Manual

4-6

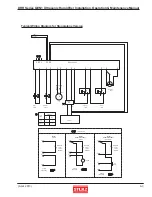

Failure Cause Checking

Remedy

No mist is

generated.

Power supply

system

Control box switch turned

off.

Visually check switch

position.

Turn switch on.

No power to the power

supply.

Measure the voltage

at power supply input

terminals.

Supply power.

Faulty power supply

Replace the

power supply.

Water supply system

Water supply valve is

closed.

Open the valve

Check if the valve is

opened or closed.

Other

Temperature sensor

detects overheating.

Check if ambient tempera-

ture and water temperature

are within specifi ed range.

Correct.

Check voltage at power

supply output terminals.

Amount of mist is

too low.

Supply voltage is low.

Correct the voltage

with the adjustment

screw on the power

supply.

Power supply system

Operating water level is

high and overfl owing.

Water supply control

system

Visually check.

See table 3) on

next page.

Humidifi er is not level.

Other

Visually check.

Correct.

Pull out the fi lter and

visually check.

Clean the fi lter.

‡Air fi lter clogging.

2) If the cause can not be located through the above checking, remove the mist guide cover

and air fl ow guide and check the interior of the water tank.

4.3 Troubleshooting and Repair

Should any failure occur, make the necessary repairs referring to the following tables. As a rule, power must

be turned off when troubleshooting is performed but if it is absolutely necessary to troubleshoot when power is

supplied, special attention must be paid to avoid electric shock and short-circuiting.

1) First the humidifi er and its surrounding area should be checked.

Mist supply is

coarse.

Power supply system

Supply voltage is high.

Check voltage at power

supply output terminals.

Fine tune the mist

quality with the

voltage adjustment

screw on the power

supply.

Measure the voltage

at power supply output

terminals.

Remarks:

The causes of failures marked ‡ can be prevented through periodic maintenance/inspection. See Section 4.1, “Periodic

General Maintenance”.

Visually check

the interior of the

water tank.

No mist is

generated.

‡ Dust and foreign material are accumulated in

the water tank.

Clean the interior of the water

tank.

‡ Dust and foreign material are accumulated in

the water tank.

Failure Cause

Checking

Remedy

Clean interior of water tank and

replace the transducer.

Amount of mist is

too low.

‡ Scale deposited on transducer surface.