(Mar, 2012)

Compact CWE Series Installation, Operation & Maintenance Manual

Air Technology Systems, Inc.

with your unit. Provide manual shut-off valves in both

the supply and return lines for servicing the unit and

for emergency isolation.

NOTE

A 60-mesh strainer is recommended to be

installed in the supply line. The strainer screen

should be cleaned periodically.

CAUTION

Chilled water cooling coils and associated

piping circuits are

pressurized (up to 100 psi)

and sealed when the unit leaves the factory.

Before installing the interconnecting piping,

release the pressure via an available stem

valve or schrader valve prior to uncapping the

pipes.

If newly installed CW supply and return piping is

used, it is recommended that the piping system be

cleaned prior to connecting it to the unit.

If solvents/

cleaning solutions are used, ensure they are

completely fl ushed from the piping before

connecting it.

Failure to do so could result in

equipment problems

CAUTION

When installing and fi lling chilled water and

optional hot water reheat loops, all air must be

bled from the piping system.

NOTE

Chilled water lines should be insulated to

prevent condensation from forming on the pipes

if ambient dew point temperatures are higher

than the fl uid temperatures.

2.7.2 Condensate Drain

2.7.2.1 Gravity Drain

A drain line is installed to drain the condensate pan. If

an optional humidifi er is used, the drain line from the

humidifi er is typically connected to the condensate

drain line. The end of the drain line is clamped inside

the cabinet. The installer must install a customer

supplied drain hose to the end of the drain line to

remove water from the cabinet. See the installation

drawing provided with your unit for the size and

location of the condensate drain line.

2.7 Piping

Connections

2.7.1 Chilled Water/Hot Water

Pipe connections for the chilled water and optional

hot water reheat piping are sweat connections. In

most cases, they terminate inside the cabinet except

units which are provided with pipe connections

protruding through the top of the cabinet.

When considering how to route the piping and wiring

for CCU (upfl ow) units furnished without top piping,

entry holes may be drilled through either the fl oor

of the cabinet or through a side panel. The SATS

installation drawing (furnished with your unit) shows

a recommended entry location. For special piping

requirements contact SATS for technical assistance.

For CCD (downfl ow) units, open areas for routing

the piping and wiring are available in the base of the

cabinet. Refer to the installation drawing provided

with your unit for the location of the openings.

If piping is brought into the side of the cabinet, ensure

adequate working space is available on that side or

if necessary cut a service opening into the adjacent

wall if the unit is installed in a corner. After the piping

is installed, seal the gaps between the pipes and the

entrance holes so air won’t leak around the pipes.

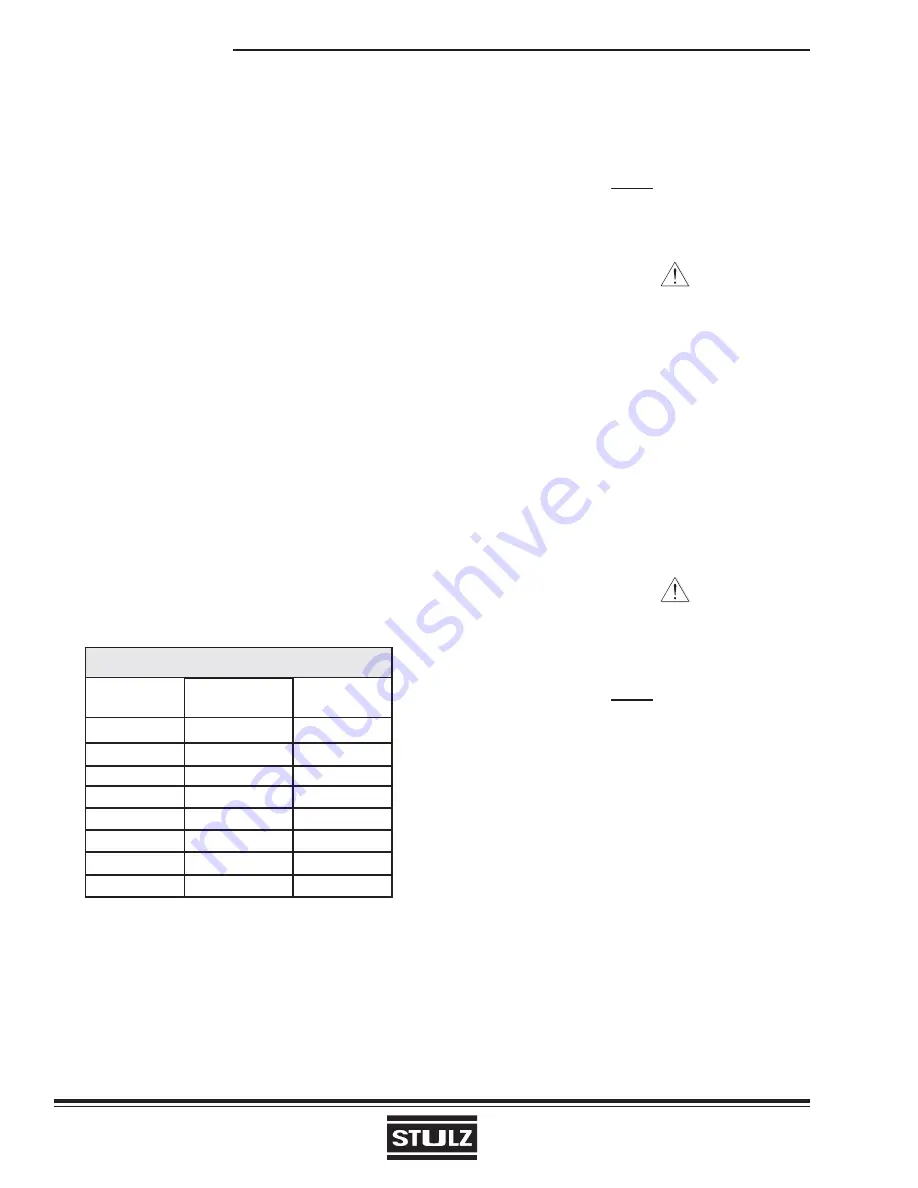

For pipe connection sizes, refer to the following table:

INLET/OUTLET PIPE SIZES

Chilled Water Hot Water

Model #

(Inches O.D.)

(Inches O.D.)

CCU/D-300

1 1/8”

7/8”

CCU/D-600

1 5/8”

7/8”

CCU/D-900

1 5/8”

7/8”

CCU/D-1200

2 1/8”

7/8”

CCU/D-1800

2 1/8”

7/8”

CCU/D-2300 2

1/8” (*or 2 5/8) 7/8”

CCU/D-2800 2

1/8” (*or 2 5/8) 7/8”

CCU/D-3600

3”

7/8”

*Special models requiring high CW fl ow are equipped with 2 5/8”.

Field piping is not necessarily the same size as the

units’ pipe connections. Piping should be sized to

match the system pressure drop and fl ow capacity,

and may require reducing fi ttings to match the

connection size on the air conditioner. An air vent and

several schrader valves are installed in the precision

A/C unit piping.

Refer to the piping diagram supplied

2-9