SECTION II

TESTING/REPLACING THE LAMP

1. Remove the black rubber lamp ring from the lamp housing.

note : A flat blade tool can be used to help pry the black rubber ring from the housing.

2. Pull the lamp/reflector assembly from the lamp housing.

3. If the lamp is the

sealed beam

type disconnect the slip-on connectors from the lamp blades.

a. Test the bulb by placing a multimeter into the continuity position and place one lead on

each lamp contact (a beep indicates a good bulb).

b. Replace the bulb if necessary.

c. The wattage of the bulb is shown on the back of the lamp in the second printed data line.

1. Example “ 6V 8W 01-28-96 1720” - the 2nd group of characters (8W) indicates the

wattage (8 watts).

2. A clear lens is a spotlight pattern (“S“); a waffled lens is a flood pattern (“F”).

4. If the lamp is the new style with a

plastic reflector and screw-in bulb

(s) follow the

instructions below.

a. Test the bulb(s) by unscrewing the plastic threaded bulb socket from the plastic reflector.

1. Pull the old bulb straight out from the socket.

2. Use a multimeter in the continuity position and place a meter lead on

each bulb lead (a beep indicates a good bulb).

b. Bulb replacement

1. Replacement bulb information (voltage and wattage) is printed on a label located on the

back of the reflector assembly .

2. Replace the bulb by aligning the pins with the holes in the socket and seat the bulb

firmly.

3. Wipe off any fingerprints from the bulb with a tissue and alcohol.

4. Screw the socket back into the reflector assembly.

a. The socket can be fully seated in the flood reflector assembly.

b. The socket can be adjusted in the spot reflector assembly.

1. Turn the Litebox on and shine it on a wall approximately 10 feet away.

2. Adjust to the desired focus by screwing the socket inward towards the fully seated

position or outwards until the point where the socket O-ring starts to leave the

surrounding screw shell of the reflector. Note : The focus should be attained

somewhere between the two limits described (try 1/4 turn out from the fully seated

position).

5. Place the reflector assembly into the lamp housing.

a. Try to dress the wires away from one another.

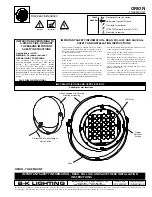

b. The reflectors need to be aligned so that the key on the reflector fits into the recesses on

the lamp housing.

c. There are two key positions on the plastic reflector assembly which allow the flood pattern

to be adjusted to either a wide or a tall pattern.

6. Replace the black rubber lamp ring.

note : A flat blade tool can be used to help pry the black rubber ring onto the lamp housing.

- 8 -