6

Doc653/30CV02A

1

2

3

4

5

6

7

14

15

16

17

18

19

20

8

9

10

11

12

13

21

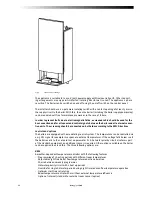

Fig. 3

Overall view

2.2

Main components

1 Flue

outlet

connection

12

On/off

switch

2 Air inlet connection

13 Condensate drain

3 Gas connection

14 Frame

4 Flow connection

15 Burner/ heat exchanger package

5

Automatic

air

vent

16

Water

fl ow temperature sensor

6 Casing

17 Gas valve

7

Return

connection

18

Venturi

8 Flue gas temperature sensor

19 Air intake silencer (tpes 45, 65 and 85)

9 Fan

20 Boiler pump (types 100 and 120 outside

10

Pressure

Gauge

the

boiler)

11 Automatic boiler controller

21 Control panel

2.2.1 Description of principal components

The boiler is made of the following components:

Fan [9]

The fan pulls in and compresses the combustion air, drawn from inside the casing of the boiler.

The fan is a DC current fan equipped with a speed feed-back signal. This speed feed-back signal

is transmitted back to the controller, which makes the necessary corrections.

Gas train

The main component of the gas train is the gas valve [17]. The gas quantity is controlled according

to the quantity of air. The air quantity varies with the speed of the fan. The gas train is equipped

with a test point through which the gas pipe can be vented or the gas inlet pressure can be meas-

ured.

Summary of Contents for ECONOFLAME R30

Page 35: ...Doc653 30CV02A 31...

Page 36: ...32 Doc653 30CV02A...