stewmac.com

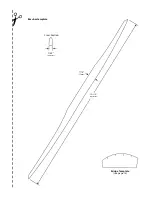

The bass bar is glued under the top, beneath the bass side

of the bridge. A pattern is supplied for shaping the bass

bar. First, cut the rough bar stock to the sizes indicated on

the

Bass bar template

(next page): 10-1/2" (267mm) long,

7/16" (11mm) tall, and 7/32" (5.5mm) wide. Next, cut out the

paper template

and glue it to the side of the bass bar and

cut the bar to shape.

Fit the bass bar to the top. You can shape the bottom of the

bar to the template by a plane, scraper, chisel, or sander.

After the initial shaping, test-fit the bar to the top. The thick-

est portion of the bass bar is located toward the butt of the

instrument. A feeler gauge will show you the gaps in the fit

of the bar

(photo)

.

By taping a piece of sandpaper to the top, you can form-fit

the bass bar by carefully working it back and forth in short

Install the bass bar

(Traditional violin makers use heated Hide Glue, but it’s dif-

ficult to use because it cools and sets very quickly. For these

instructions we use Titebond, a better choice for first-time

builders.)

When the glue has dried, trim and scrape the purfling to

lower its height so that it’s flush with the top and back sur-

faces. Don’t overwork it at this stage. You’ll final-sand and

smooth these purflings later, after the top is glued on.

For the tight curves, create your own bending iron using a

piece of copper plumbing pipe and a propane torch

(above

photo)

. Heat the pipe, keeping the temperature low, and

bend the damp purfling against the copper.

The dampened purfling is left to dry in its curved shape.

While one joint is drying, you can work on another area

(photo right)

. Remove the dry-fit purflings, handling

them gently. Glue the pieces in place with Titebond glue.

������

��������

����

������

��

��

��������

�����

�������

�������

�������

����������

cross-wise strokes

(photo)

. This will remove any small gaps

between the top and bar. Once it fits, remove the template

and sand the bass bar smooth.

4

Summary of Contents for 5342

Page 1: ...Violin Kit 5342 Assembly Instructions www stewmac com ...

Page 2: ......

Page 9: ... ...

Page 10: ......

Page 23: ......