14

15

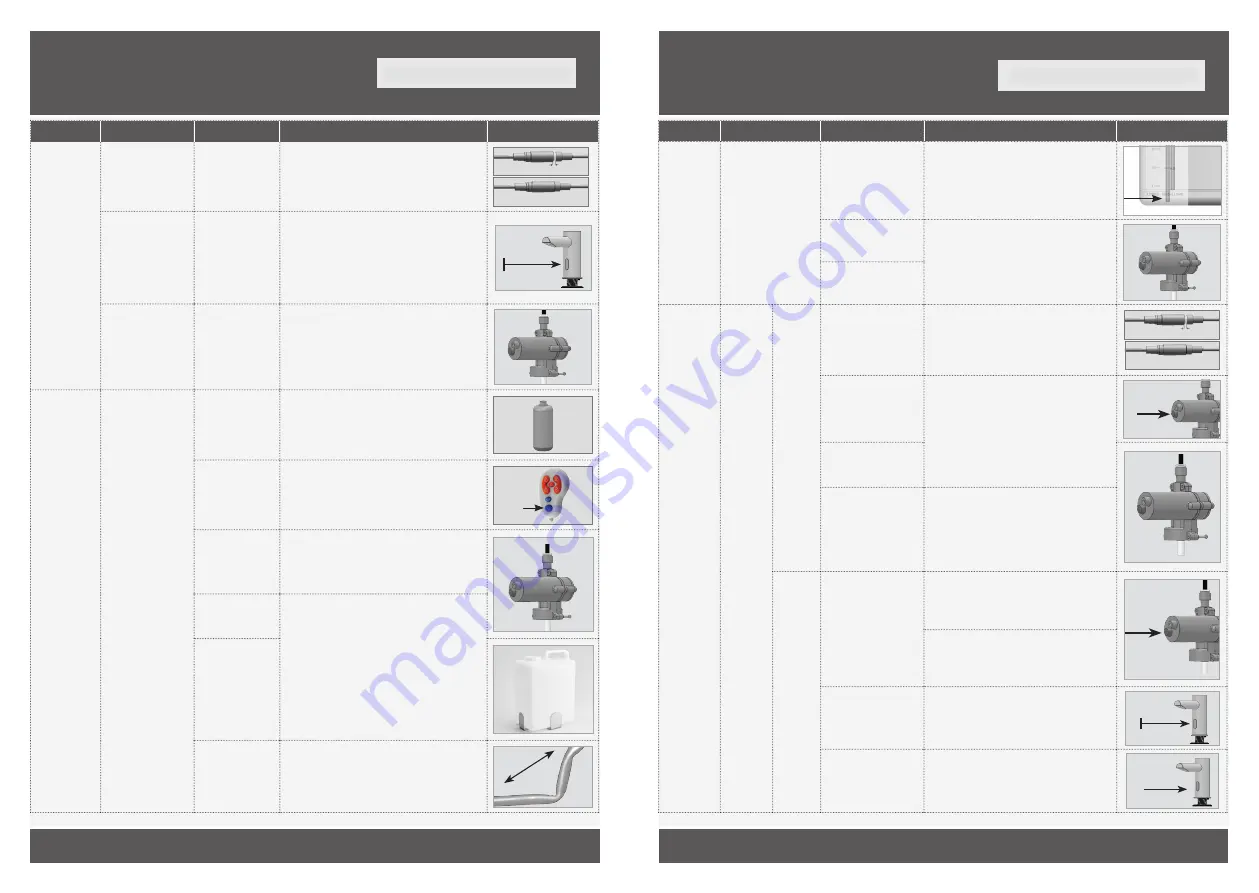

TROUBLESHOOTING

lIquId SoaP dISPenSeRS

lIquId SoaP dISPenSeRS

SPARE PARTS LIST

Illustration

Solution

Cause

Investigation

Indication

O-RING VISIBLE –

NOT CONNECTED PROPERLY

ONLY THE GROOVES ARE VISIBLE –

CONNECTED PROPERLY

The connector should be inserted fully until

white o-ring is not visible. Remove the o-ring if

necessary

AUx connector not

fully inserted

Continuous

discharge from the

nozzle

False

activation:

Soap

dispensing

Min 1.5 M

Eliminate any cause of reflection and if

necessary use appropriate remote control to

shorten detection range.

Reflection issue

from other object

Random discharge

from the nozzle

Replace the Pump. Rinse warm water through

the pipe and the body of the soap dispenser all

the way to the nozzle.

Damaged pump

due to high

viscosity or debris

in pipes

Soap discharging

from pump housing.

Fill with soap with correct viscosity (100 - 3800

cPs) and prime pipes using the fill button on

remote control.

Soap tank is

empty

Pump is making

sounds when sensor

is activated

Soap not

dispensing

Press

FIll

Button

Prime the soap dispenser by pressing the fill

button on the remote or by pressing the refill

button located at the bottom of the pump, until

soap exits the nozzle.

Soap dispenser

has not been

primed

Replace the Pump

Damaged pump

(discharge from

housing)

Run warm water through pipe, pump, and body

all the way to the nozzle. Replace with soap of

correct viscosity.

NOTE: Using the soap dispenser with high

viscosity soap may cause permanent damage to

the pump and shorten the lifecycle.

Debris or dried

soap in the pipe

or tank

Soap Viscosity

(100 - 3800 cPs)

High viscosity

soap

(> 3800 cPs)

Unbend or straighten pipes.

Bent pipes

Illustration

Solution

Cause

Investigation

Indication

Ensure that the tip of the inlet pipe is fully

immersed in the soap. For earlier models

check that the pipe has not been pushed so

far that the tip has risen above soap level.

The new models have an additional sleeve

for the pipes preventing this from occuring.

Tip of inlet pipe is not

immersed in soap

Pump is making

sounds when sensor

is activated

Soap not

dispensing

Check that all pipes are connected firmly to

the pump. If necessary remove pipe, cut 7

mm and replace firmly.

6mm pipe connecting

pump to dispenser

outlet has come loose

8 mm pipe connecting

pump to tank has come

loose

O-RING VISIBLE –

NOT CONNECTED PROPERLY

ONLY THE GROOVES ARE VISIBLE –

CONNECTED PROPERLY

The connector should be inserted fully until

the white o-ring is not visible. Remove the

o-ring if necessary

AUx connector not fully

inserted

Sensor is

blinking

when

hand is

placed in

front

Pump

is not

making

sound

when the

sensor is

activated

Soap not

dispensing

Press

Replace the Pump. Rinse warm water through

the pipe and the body of the soap dispenser

all the way to the nozzle.

Refill button o n pump

does not activate the

pump.

Damaged pump

(discharge from

housing).

Run warm water through pipe, pump, and

body all the way to the nozzle. Replace with

soap of correct viscosity.

NOTE: Using the soap dispenser with high

viscosity soap may cause permanent damage

to the pump and shorten the lifecycle.

Debris or dried soap in

the tank or tubing

Refill

button

Transformer: Check operation with functioning

transformer. Where necessary replace with

appropriate transformer. For part numbers see

spare parts list.

Refill button on pump

does not activate the

pump.

Sensor

is not

blinking

when

hand is

placed in

front

Battery: Check operation with functioning

battery pack. Where necessary, replace

batteries or replace the battery pack: Battery

pack (without batteries)

Min 1.5 M

Eliminate any cause of reflection and use

appropriate remote control to shorten

detection range.

Reflection issue from

other object

Replace

sensor

If the above two solutions have not resolved

this issue replace with appropriate sensor. For

part numbers see spare parts list.

Damaged sensor