45

As a policy of continual improvement, STAUFF reserves the right to alter the specification without prior notice.

201.031

Date of Issue: 06 November 2018

Use the software to configure any CAN-bus specific parameters required by your CAN-bus

network, for example configure a CAN-bus message ID and baud rate

Figure 6.29

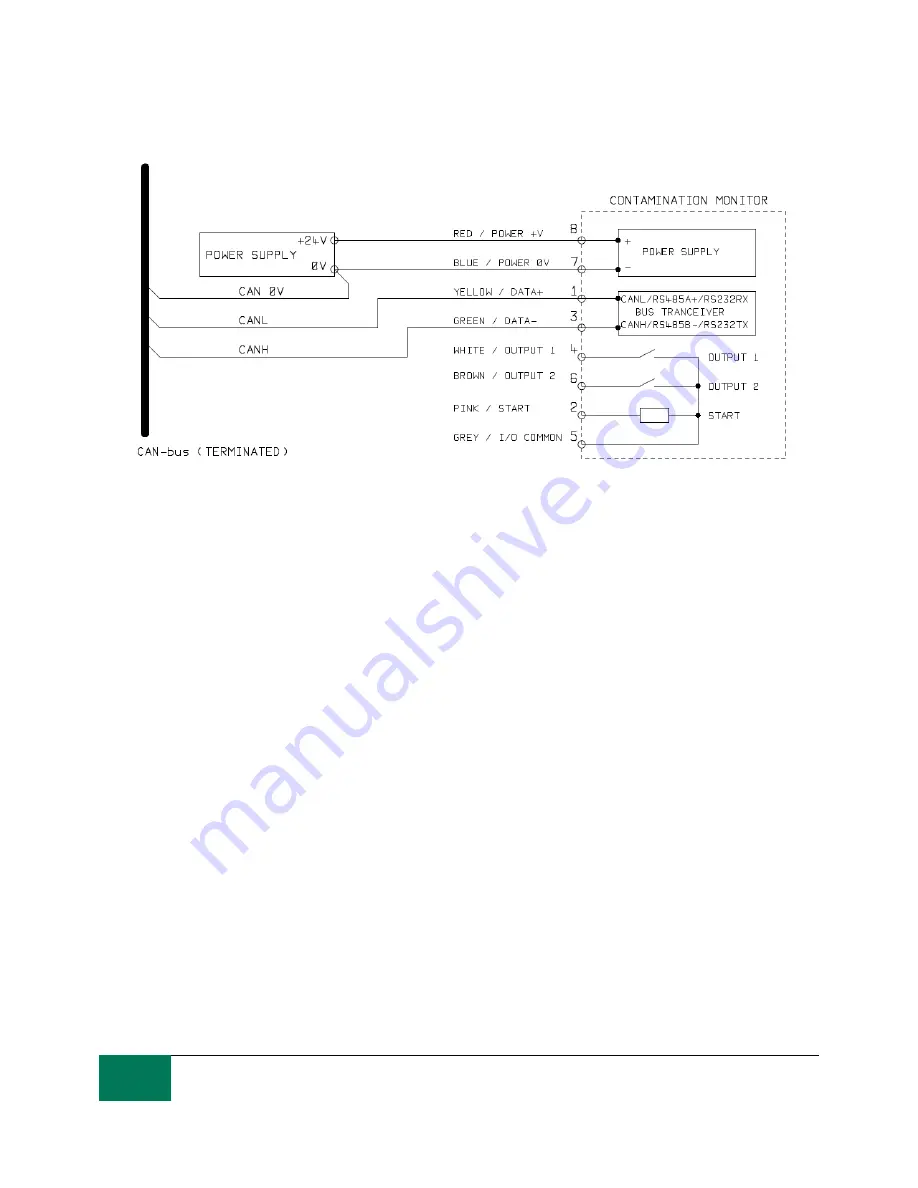

Connect the LPM to your CAN-bus network and provide a 24VDC power supply, as per figure

6.29.

The LPM automatically emits the test result message after each set test interval.

Configure your CAN-bus controller to listen for the messages configured above.

The LPM requires a DC power supply and the two CAN-bus signals CANL and CANH, as shown

in Figure 1. The numbers shown are the pin numbers of the circular connector that plugs into the

LPM.

CAN-bus requires the network to be terminated at each end. This must be done externally to the

LPM.

The CAN-bus signals CANL and CANH are referred to the system 0V supply. These should stay

within the common mode range allowed by the ISO-11898-4 CAN-bus standard relative to the

LPM 0V connection. This range is -2V to +7V. This can be normally be ensured by connecting

together the LPM 0V and the 0V of the CAN-

bus controller. The “CAN 0V” wire shown indicates

this link. (Not needed if both CAN-bus controller and LPM are connected to a vehicle chassis or

otherwise “Earthed”.)

There are other wires available for switched alarm and start signals (optional). These are

documented separately in section 6.1.2.

6.4.2.2 Configuration

6.4.2.2.1 Use PC Software for Configuration

The free LASPAC-View software package is needed in order to initially configure the LPM. Once

configured, the unit can be left connected to the CAN-bus network.

The LPM was designed to be as flexible as possible. There are large number of options for setting

operating modes, test result formats, alarm settings, downloading stored data etc.