19

As a policy of continual improvement, STAUFF reserves the right to alter the specification without prior notice.

201.031

Date of Issue: 06 November 2018

6.1.2.3 Machine Connector - Serial Interface

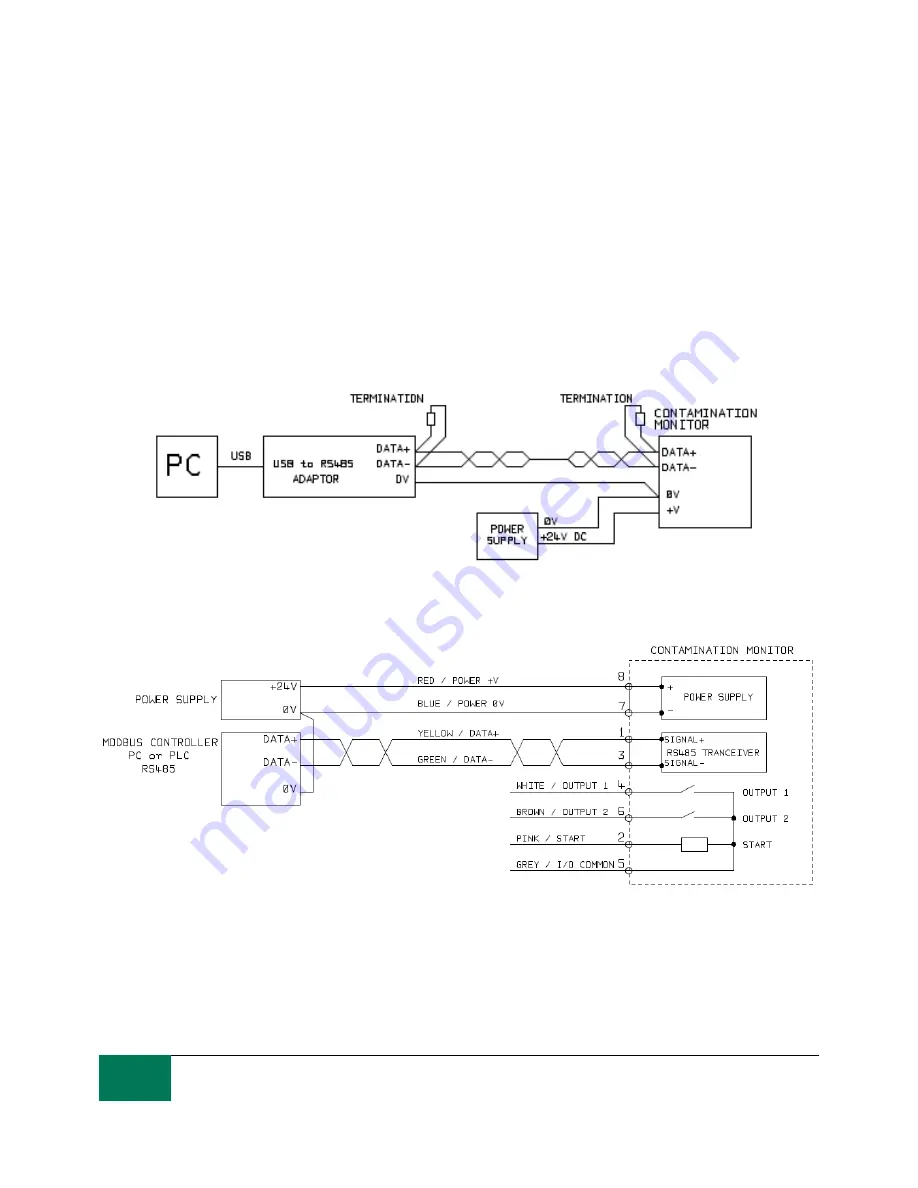

An RS485 or CANbus interface can optionally be connected to pins 1 and 3 (yellow and green). This can

be a PLC running customer software, or a PC with a RS485 adaptor running the supplied LASPAC-View

software. To provide a reference the RS485 0V connection should also be linked to the LPM 0V (as

shown on figure 6.3).

The standard LPM control protocol is Modbus RTU. Modbus is a freely available open standard for

industrial control. Adapters are available to interface to other industrial control busses. The standard

LASPAC-View software from Stauff itself uses Modbus to communicate with the LPM, but it is also

possible for customers to implement their own controllers (section Modbus).

The CANbus protocol can also be used, see separate LPM-CANbus manual.

Figure 6.3a PC Control Example

Figure 6.3b Modbus Controller Example

Figure 6.3a shows a single LPM linked to a PC, using a USB-RS485 adaptor. Figure 6.3b shows a

slightly different method. 100 Ohm termination resistors should be fitted as shown for long cables, for

example over 10m. Twisted pair wiring should be used for any length over 2m.