40

As a policy of continual improvement, STAUFF reserves the right to alter the specification without prior notice.

201.031

Date of Issue: 06 November 2018

This is used when controlling tests from a PLC using switched outputs. The PLC gives a start signal,

then monitors the “Test Complete” output. If the test has failed it can detect this with the ”not clean”

signal.

“Continuous testing”’ should not be selected for this mode.

Alarm Mode 6: Testing Not-Clean

Output 1

Output 2

Turns on When

Testing

>Lower

Intended Function

Test in progress Signal

“Not Clean” Signal

This is similar to mode 5 above. The difference is that output 1 is active during the test and turns off at

test end.

“Continuous testing”’ should not be selected for this mode.

Alarm Mode 7… Customer Requested Modes

Other alarm modes will be defined as and when customers request them.

6.4 Standard Communication Protocols

6.4.1 Modbus

The LPM can be controlled via commands on its serial (RS485) interface, using the Modbus RTU

protocol. It is possible to control every aspect and setting of the LPM, as is done by the Stauff LASPAC-

View control software. All results and counts are available in all supported formats. We suggest using

LASPAC-View to initially configure the LPM and check it is performing correctly, and then the customer-

written software only has to read the test results. This could be used to integrate the LPM measurements

with a general machine control, vehicle control or factory monitoring system.

Customers wishing to implement their own Modbus controller software will need to refer to the rest of this

section with further details in section 11.1 and 11.2.

The simplest arrangement is to configure the LPM to test continuously, with a set interval between tests.

For example; a Test Duration of 2 minutes and a Test Interval of 10 minutes.

The Start Testing Automatically selection can be used so that the unit does not require a start signal.

Then, the most recent test results can be read from the appropriate Modbus Registers.

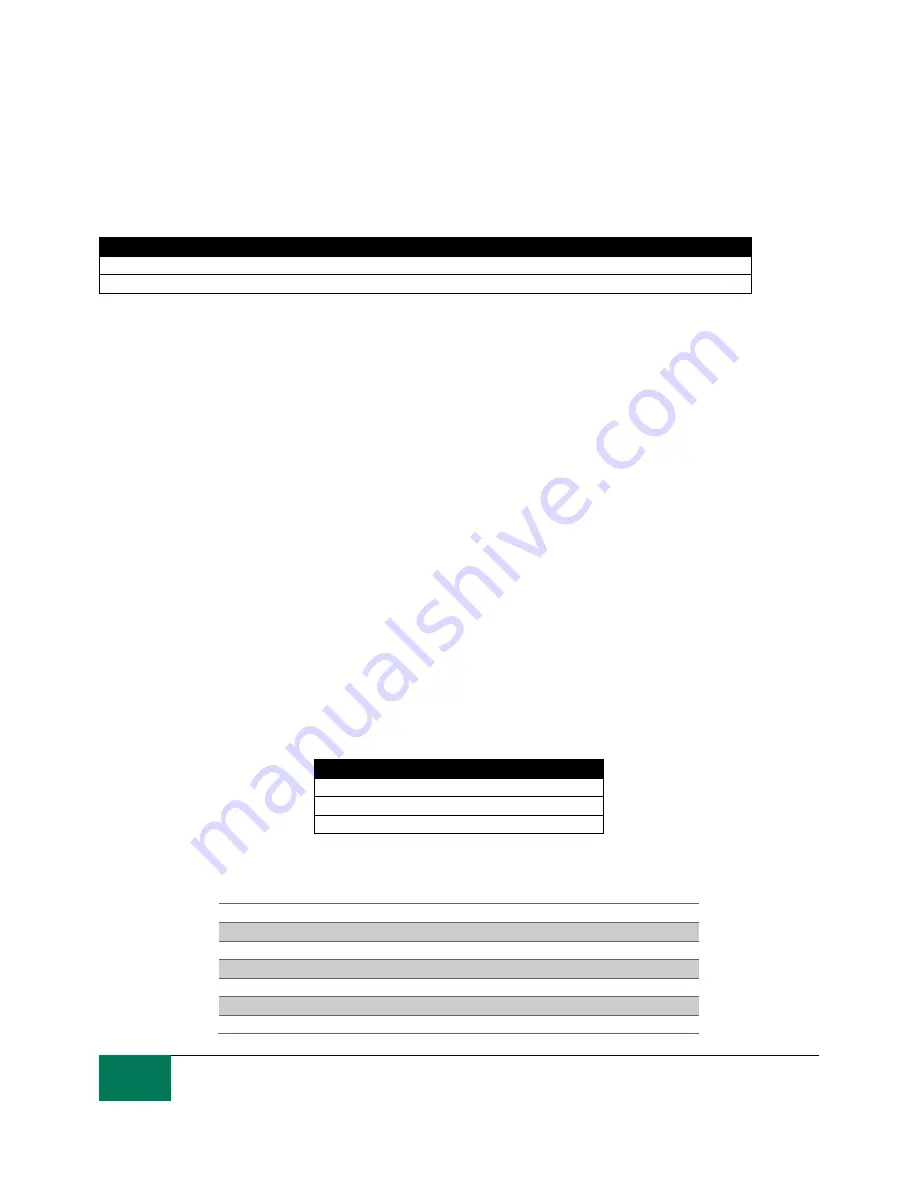

Register

Function

56

4μm Result Code

57

6μm Result Code

58

14μm Result Code

6.4.1.1 Set Up

Protocol Type

RTU (not ASCII)

Data Bits

8

Stop Bits

1

Parity

Required, Even or none

Baud

Auto-sensing 1200-115200

Signaling

RS485

Node Address

4 (or user set)

Figure 6.29 Settings