TDM

Universal Time Delay Module

INSTALLATION INSTRUCTIONS

8701 Castle Park Drive

Indianapolis, Indiana 46256

Telephone: (800) 842-2545/(317) 842-2545

www.mssedco.com

Page 1

(82A044) TDMv0605

Section 1

General Description

The TDM is a multipurpose timing module that can be

used for a variety of applications. Its unique design and

open architecture allows the TDM to be used in any

application that requires timing control of up to two

outputs with up to four inputs. Common applications

include: simple time delay, vestibule door sequencing

(only one device required) and electric lock/automatic

door operator sequencing.

The four inputs on the TDM allow sequencing or

independent operation of the two outputs. Input 1 will

sequence Outputs 1 then 2. Input 2 will sequence

Outputs 2 then 1. Input 3 will operate Output 1

independently. Input 4 will operate Output 2

independently.

Both outputs on the TDM are fully programmable for "on

time" duration as well as the delay time between the two

outputs from 0 to 99 seconds.

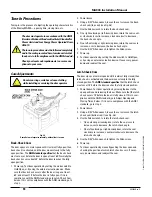

CAUTION:

Devices to be controlled by the TDM

must be low voltage (12-24V) but can be

inductive loads. Surge suppressors are standard

on the TDM.

WET/DRY CONTACT OPTION:

The TDM has the option to supply power to Relay Output

1 contacts. This is known as having a "Wet" contact

instead of the conventional "Dry" contact closure. To use

output 1 as a "Wet" contact, change the jumper setting

(see Figure 1). The voltage supplied to Output 1 will be

the same as the voltage supplied to the input power wires

of the TDM.

WARNING:

Changing jumper settings to enable

the “Wet” Contact option will apply a voltage to

the Output 1 relay contact. Please ensure that

any device connected to this output is capable of

accepting voltage. Failure to do so may result in

damage to the device.

Section 2

Basic Installation

The physical placement of the TDM is typically in the door

operator housing area since the power supply and

operator control are already in this location. The TDM

layout and wiring connections are shown in Figure 1.

Included on the following pages are detailed wiring and

programming instructions for three common applications.

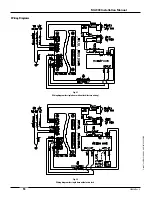

Figure 2: Simple Time Delayed Output

Figure 3: Electric Lock & Door Operator Sequencing

Figure 4: Vestibule Door Sequencing

After successfully wiring the TDM for your application,

refer to Figure 5 for the operating display explanations

and additional programming options. For additional

technical assistance, please contact us toll-free at 1-800-

842-2545.

NOTICE:

These instructions are provided for your

convenience. Please verify your installation is in

compliance with all local electrical codes.

Section 3

Technical Data

Model....................................... TDM

Input Power.............................. 12-24V AC or DC

Power Consumption................ 2W Maximum

Output Contacts....................... Form C, Rated at 3 Amps

Relay Contact Rating............... 3A:120V AC; 3A:60V DC

Temperature Rating................ -22°F to 158°F

(-30°C to 70°C)

Weight...................................... <0.25 lbs.

Physical Size............................ 4.75"L x 2.125"W x 0.75"H

Section 4

Warranty

MS SEDCO guarantees this product to be free from manufacturing

defects for 1 year from date of installation. Unless MS SEDCO is

notified of the date of installation, the warranty will be in effect for

1 year from the date of shipment from our factory. If, during the

first year, our motion detector or support device fails to operate

and has not been tampered with or abused, the unit can be

returned prepaid to factory and it will be repaired free of charge.

After 1 year, the unit will be repaired for a nominal service charge.

This limited warranty is in lieu of all other warranties expressed

or implied, including any implied warranty of merchantability,

and no representative or person is authorized to assume for MS

SEDCO any other liability in connection with the sale of our

products. All warranties are limited to the duration of this

written warranty. In no event shall MS SEDCO be liable for any

special, incidental, consequential or other damages arising

from any claimed breach of warranty as to its products or

services.

Questions? Call us toll-free at 1-800-842-2545 or

visit us online at www.mssedco.com.

!

!

!

Summary of Contents for MA900n

Page 3: ...MA900 Installation and Owner s Manual 203936 Rev C ...

Page 4: ... 2005 The STANLEY WORKS ALL RIGHTS RESERVED 203936 Rev C MA900 Installation Manual 2 ...

Page 29: ... 2005 The STANLEY WORKS ALL RIGHTS RESERVED 203936 Rev C MA900 Installation Manual 27 Notes ...

Page 30: ... 2005 The STANLEY WORKS ALL RIGHTS RESERVED 203936 Rev C MA900 Installation Manual ...