9

Operating Instructions

Check Power Source

Connect Hoses

1. Using a calibrated flowmeter and pressure

gauge during the intial set-up, check that the

hydraulic power source develops a flow of 4-

12 gpm/ 15-45 lpm at 1000-2000 psi/ 70-140

bar.

2. Make certain that the hydraulic power source

is equipped with a relief valve set to open at

2100 psi/ 145 bar maximum.

1. Wipe all hose couplers with a clean lint-free

cloth before making connections.

2. Connect hoses from the hydraulic power

supply to the tool quick disconnects. It is a

good practice to connect the return hose first

and disconnect it last to minimize or avoid

trapped pressure within the drill.

3. Observe the arrow on hose couplers to ensure

that the flow is in the proper direction. The

male coupler on the circuit hose end is the

supply (pressure) coupler.

4. Make sure the circuit PRESSURE hose (with

male quick disconnect) is connected to the

port at the back of the drill handle. The circuit

RETURN hose (with female quick disconnect)

is connected to the port closest to the trigger.

5. Move the hydraulic circuit control valve to the

position to direct hydraulic flow to the

drill.

ON

5. Press the drill against the work and squeeze

the trigger.

The drilling method used is determined by the

material being drilled and the size and depth

requirements of the hole.

Ductile material such as metal or wood is drilled

efficiently when a steady down force is applied to

the drill center to cause the bit to slice chips of

material from the hole bottom. When drilling in

metal, use a cutting lubricant to prolong bit life

and reduce the amount of force required to drill

effectively.

Large drill holes are more productively created

from small drill holes. Drill bits are incrementally

selected to enlarge the hole until the desired hole

size is obtained. Each bit selected must always be

too large to thread and jam into an existing hole;

otherwise the bit may break and endanger the

operator.

NOTE: If uncoupled hoses are left in the

sun, pressure increase inside the hose

may result in making them difficult to

connect. Whenever possible, connect the

free ends of the hoses together.

Drill Operation

1. Observe all safety precautions.

2. Place the selected drill bit fully into the chuck.

Center the bit and tighten the chuck using the

key provided. Remove the key and store away

from the drill.

3. Momentarily press the trigger to ensure that

the drill bit rotates clockwise and runs true.

4. Select a work position that gives secure

footing and balance while operating the drill.

CAUTION

Make certain that the chuck has been securely mounted.

Summary of Contents for DL09150

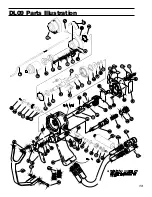

Page 13: ...DL09 Parts Illustration 13 ...