11

Tool will not start. Power not being supplied.

Check to make certain that both

hoses are connected.

Defective quick disconnects.

Turn hydraulic circuit control valve

ON.

Check each quick disconnect

separately. Replace as necessary.

Symptom

Possible Cause

Solution

This section describes how to find and resolve problems users may experience. If a situation occurs that is not covered,

call your Stanley Customer Service representative for assistance.

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the tool, always check that the hydraulic power source is supplying the correct

hydraulic flow and pressure to the tool as listed in the table. Use a flowmeter known to be accurate. Check the flow

with the hydraulic oil temperature at least 80

° F/27° C.

WARNING

Inspecting the tool or installing parts with the hydraulic hoses connected can result in severe personal injury or equipment

damage.

To prevent accidental startup, disconnect the hydraulic power before beginning any inspection or installation task.

Troubleshooting

continued

Low drilling

torque.

Relief valve setting too low.

Set relief valve at 2100 psi/ 145 bar.

Fluid restriction in hose or valve.

Excess flow and pressure loss.

Locate and remove restriction.

Fluid not warmed-up. Preheat

system.

Use correct fluid.

Hoses too long for hose I.D. Use

shorter hose.

Hoses I.D. too small for hose

length. Use larger I.D. hose.

Tool speed too

high.

Fluid flow rate is excessive.

Check circuit flow rate; add a

proper flow control valve.

Hydraulic pressure and return

hoses reversed.

Correct hose connections. Pressure

should be to the handle port away

from the trigger, return is near the

trigger, or see your Authorized

Dealer for servicing.

Low tool speed.

Fluid flow rate is too low.

Check circuit flow rate.

Oil leaks around

gear housing.

Main shaft seal o-ring leaking.

See your Authorized Dealer for

servicing.

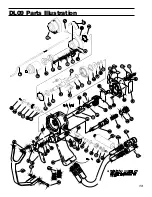

Summary of Contents for DL09150

Page 13: ...DL09 Parts Illustration 13 ...