Warranty

Stanley Hydraulic Tools (hereinafter called “Stanley”), subject to the exceptions contained below, warrants new hydraulic tools for a period of one

year from the date of sale to the first retail purchaser, or for a period of 2 years from the shipping date from Stanley, whichever period expires first,

to be free of defects in material and/or workmanship at the time of delivery, and will, at its option, repair or replace any tool or part of a tool, or new

part, which is found upon examination by a Stanley authorized service outlet or by Stanley’s factory in Milwaukie, Oregon to be DEFECTIVE IN

MATERIAL AND/OR WORKMANSHIP.

New parts which are obtained individually are warranted, subject to the exceptions herein, to be free of defects in material and/or

workmanship at the time of delivery and for a period of 6 months after the date of first usage. Seals and diaphragms are warranted to be free of

defects in material and/or workmanship at the time of delivery and for a period of 6 months after the date of first usage or 2 years after the date of

delivery, whichever period expires first. Warranty for new parts is limited to replacement of defective parts only. Labor is not covered.

Freight costs to return parts to Stanley, if requested by Stanley for the purpose of evaluating a warranty claim for warranty

credit, are covered under this policy if the claimed part or parts are approved for warranty credit. Freight costs for any part or parts which are not

approved for warranty credit will be the responsibility of the individual.

Seals and diaphragms installed in new tools are warranted to be free of defects in material and/or workmanship for a

period of 6 months after the date of first usage, or for a period of 2 years from the shipping date from Stanley, whichever period expires first.

Cutting accessories such as breaker tool bits are warranted to be free of defects in material and or workmanship at

the time of delivery only.

Components which are not manufactured by Stanley and are warranted by their respective

manufacturers.

a. Costs incurred to remove a Stanley manufactured component in order to service an item manufactured by other

manufacturers.

Alterations or modifications to any tool or part. All obligations under this warranty shall be terminated if the

new tool or part is altered or modified in any way.

Any failure or performance deficiency attributable to normal wear and tear such as tool bushings, retaining pins, wear plates,

bumpers, retaining rings and plugs, rubber bushings, recoil springs, etc.

To the fullest extent permitted by applicable law, in no event will STANLEY be liable for any

incidental, consequential or special damages and/or expenses.

Damage caused by improper storage or freight handling.

Loss of operating time to the user while the tool(s) is out of service.

Any failure or performance deficiency attributable to a failure to follow the guidelines and/or procedures as outlined in

the tool’s operation and maintenance manual.

Any failure or performance deficiency attributable to not maintaining the tool(s) in good operating condition as outlined in the

Operation and Maintenance Manual.

Any failure or performance deficiency attributable to excess hydraulic pressure,

excess hydraulic back-pressure, excess hydraulic flow, excessive heat, or incorrect hydraulic fluid.

Any failure or performance deficiency attributable to repairs by anyone which in Stanley’s sole judgement caused

or contributed to the failure or deficiency.

Any failure or performance deficiency attributable to mis-application. “Mis-application” is defined as usage of products for

which they were not originally intended or usage of products in such a matter which exposes them to abuse or accident, without first obtaining the

written consent of Stanley. PERMISSION TO APPLY ANY PRODUCT FOR WHICH IT WAS NOT ORIGINALLY INTENDED CAN ONLY BE OBTAINED

FROM STANLEY ENGINEERING.

STANLEY ASSUMES NO LIABILITY FOR WARRANTY CLAIMS SUBMITTED FOR WHICH NO TOOL REGISTRA-

TION IS ON RECORD. In the event a warranty claim is submitted and no tool registration is on record, no warranty credit will be issued without first

receiving documentation which proves the sale of the tool or the tools’ first date of usage. The term “DOCUMENTATION” as used in this

paragraph is defined as a bill of sale, or letter of intent from the first retail customer. A WARRANTY REGISTRATION FORM THAT IS NOT ALSO ON

RECORD WITH STANLEY WILL NOT BE ACCEPTED AS “DOCUMENTATION”.

This limited warranty and the obligation of Stanley thereunder is in lieu of all other warranties, expressed or implied including merchantability or

EXCEPTIONS FROM WARRANTY

NEW PARTS:

FREIGHT COSTS:

SEALS & DIAPHRAGMS:

CUTTING ACCESSORIES:

ITEMS PRODUCED BY OTHER MANUFACTURERS:

ALTERATIONS & MODIFICATIONS:

NORMAL WEAR:

INCIDENTAL/CONSEQUENTIAL DAMAGES:

FREIGHT DAMAGE:

LOSS TIME:

IMPROPER OPERATION:

MAINTENANCE:

HYDRAULIC PRESSURE & FLOW, HEAT, TYPE OF FLUID:

REPAIRS OR ALTERATIONS:

MIS-APPLICATION:

WARRANTY REGISTRATION:

NO ADDITIONAL WARRANTIES OR REPRESENTATIONS

16

Summary of Contents for DL09150

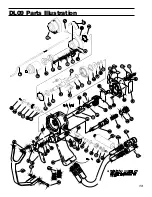

Page 13: ...DL09 Parts Illustration 13 ...