COMMISSIONING

Burner Set-up

1.

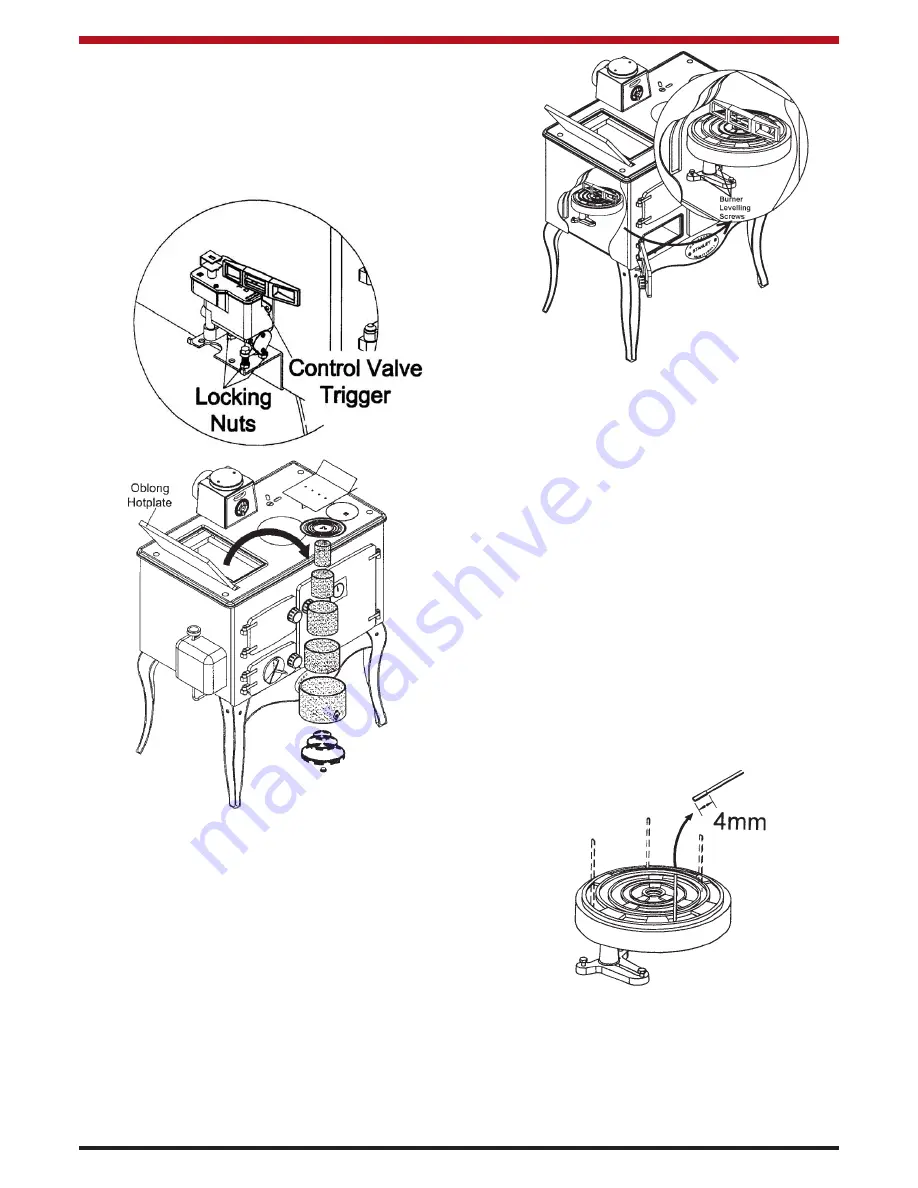

Using a spirit level, check that the control

valve is level in all directions. Adjust the

locking nuts on the valve legs if levelling is

necessary. (See Fig.20).

Fig..20

Fig.21

2.

Check that the burner is level in all direc-

tions. If levelling is necessary remove the

fire valve phial from the fire valve bracket

and place it to one side of burner compart-

ment. Loosen the 1/4” bolt, holding down

the burner stand. The level is adjusted by

adjusting the three M8 bolts on the base of

the burner stand (See Fig. 22). Re-tighten

the 1/4” bolt when finished adjusting the

M8 bolts.

Fig.22

13

3.

Push the control valve trigger up to set the

valve (See Fig.20). Turn the control knob

to 6 for 10 minutes to commence filling the

burner. If oil does not flow to the central

reservoir after 5 minutes, it may be neces-

sary to bleed the oil line at the elbow con-

nector in the burner compartment.

4.

Check the oil in the burner rings. The oil

level should be 4mm. (See Fig. 23). If the

level is greater than required, the control

valve should be lowered. The control valve

bracket can be moved up and down by loos-

ening the M4 lock nuts. If the level is less

than required, the control valve should be

raised until the oil level is correct. Each time

an adjustment is made, the oil in the central

reservoir and burner rings should be soaked

up with absorbent paper and the filling

process repeated.

Note:

Do not check oil depth adjacent to fuel ports.

Fig.23

5.

After any adjustments to the control valve,

check that it is level in all directions.

6.

Once the oil depth and burner level are set,

the burner can be re-assembled. Refer to

Burner Assembly section.

7.

Attach the control spindle to the control valve

using the M8 lock nut, and place the oil con-

trol valve cover in place over the valve.