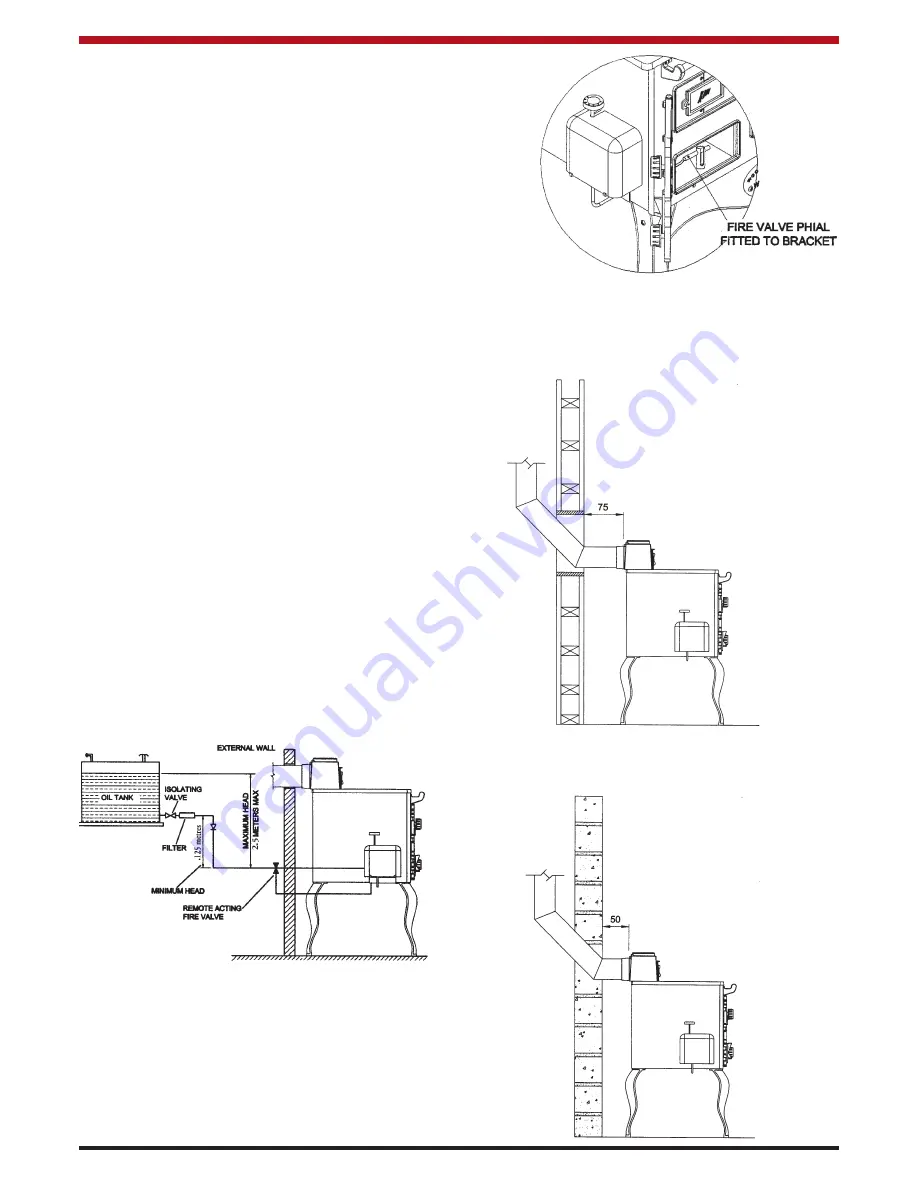

An oil filter (5 - 10 micron) and stop valve must be fit-

ted to the fuel feed line and located near the supply

tank and facilities should be provided to enable it to

be serviced without draining down the oil supply sys-

tem. (See fig.4).

At the point where the oil line enters the building, the

oil line must be fitted with an approved remote act-

ing fire valve which meets the requirements of B.S.

5410 : Part 1, fitted with the appropriate length of

capillary. The temperature rating limit should be

90

o

C. The heat sensoring phial of the fire valve

should be passed through the base of the burner

compartment and fitted through the fire valve brack-

et provided in the burner compartment (see Fig.5). It

is absolutely essential that the fire valve is located

externally and is as close as possible to the appli-

ance. For existing installations where the oil supply

is built into the structure internally, the remote acting

fire valve should be fitted where the oil supply line is

first exposed internally. This type of layout is not

recommended for new installations.

These requirements are further explained within the

following documents:

*

BS 5410: Part : Code of practice for Oil

Firing installations up to 45 kW output

capacity for space heating and hot water

supply purposes.

*

OFTEC Technical Information Book Three:

Installation Requirement for Oil Fired Boilers

and Oil Storage Tanks.

*

The Building Regulations Part J: England

Wales, Part F - Section 4 Scotland and Part

L Northern Ireland.

CLEARANCES TO COMBUSTIBLES

The minimum clearance to combustible materials

should be maintained at least 75mm (3”) from rear of

cooker (see Fig. 6).

Fig.4

Fig.5

6

Fig.6

The minimum clearance to non-combustible materi-

als should be maintained at least 50mm (2”) from

rear. (see Fig.7)

If there are other oil fired appliances connected to

the oil storage tank especially appliances with oil

pumps e.g. oil fired boilers or stoves, it is recom-

mended that a separate oil supply line is taken from

the oil tank to the cooker. The separate oil supply

line to the cooker will avoid the possibility of the

pumped appliance taking oil from the cooker burner.

A suitable shut off valve should be fitted near the

cooker and be accessible at all times.

NOTE:

Ensure that the fire valve phial is not touch-

ing any point of the base casting.

Fig.7