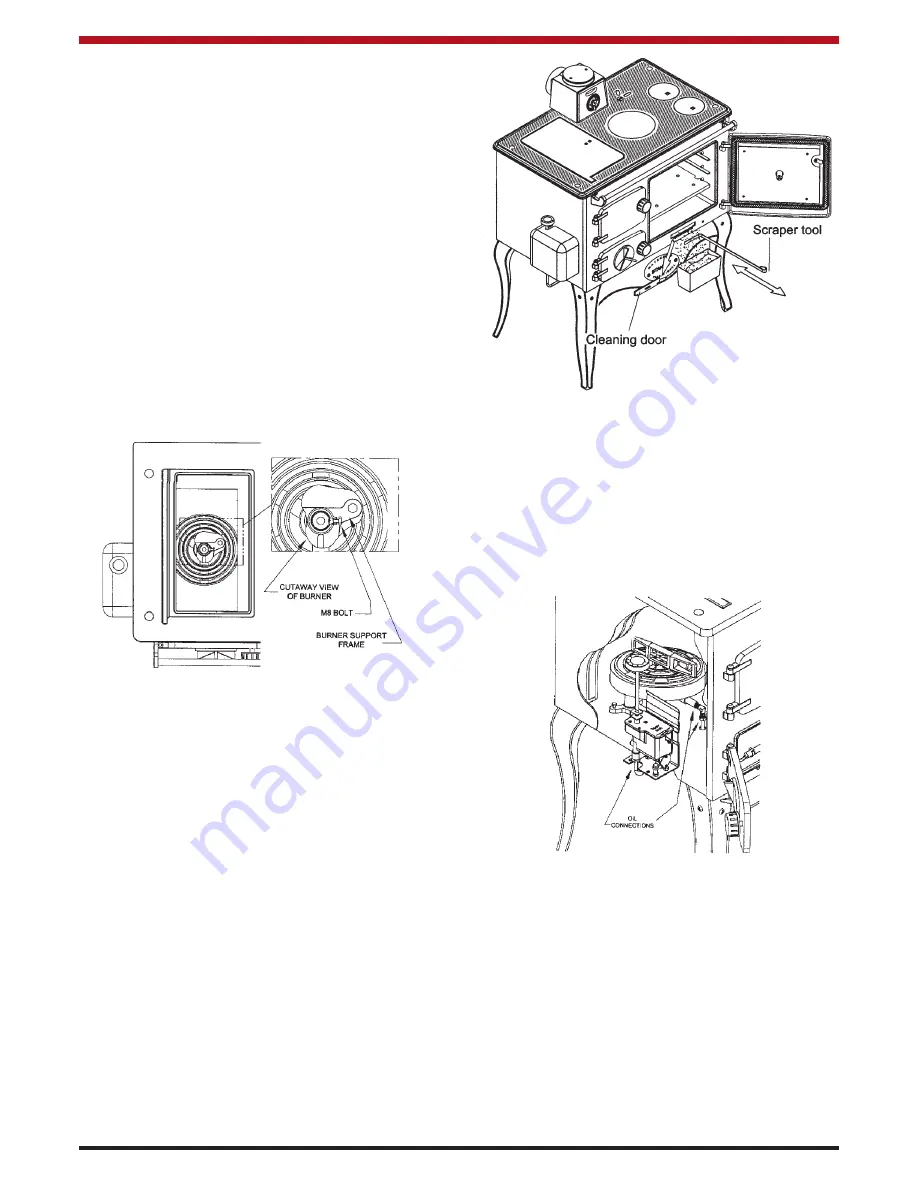

Fig.31

Fig.33

16

Fig.32

1.

Open the oblong hotplate and remove the

burner shells, wicks, centre well cap, baf-

fle and burner lid from the fire box.

2.

Open the ashpit door and place the fire

valve phial to one side of the burner com-

partment, so that the burner base can be

accessed. Remove the air distribution baffle.

3.

Disconnect the oil line from the burner and

remove the burner from the firebox by undo-

ing the M8 bolt on the side of the burner sup-

port frame (See Fig.31).

4.

Remove any dirt from the burner rings and

ensure that the ports between the rings are

clear.

5.

Remove the simmering plate and cleaning

cups and brush any soot deposits into the

firebox.

Vacuum any dirt from the firebox base and if

necessary, clean the viewing glass.

6.

Remove the base cleaning door and rake the

deposits, from underneath the oven through

the cooker front into a container using the

scraper tool. (See Fig.32).

7.

Open the bonnet door and check for any soot

deposits in the flue. If there is evidence of

substantial soot build-up, the flue may need

to be cleaned.

8.

Replace the burner in the firebox and recon-

nect the oil line to the burner.

9.

Check that the burner and oil control valve

are level in all directions. Check all oil con-

nections to ensure that there are no leaks.

(See Fig.33).

10.

Turn the control valve to 6 to fill the burner.

Check that the correct level of oil is present.

(See Commissioning Section.)

11.

Fit new wicks in the burner rings, ensuring

that the cut-outs in the wicks line up with the

fuel ports between the burner rings. (The

wicks should be replaced every time the

cooker is serviced).

12.

Fit the burner assembly as described in the

Burner Assembly Section.

13.

Reposition the fire valve phial. Close the

ashpit door.

14.

Light the stove and check the flame pattern

(See Commissioning Section).

Flexible oil lines should be inspected at each

and every service visit. There are varying types

of line with guarantee periods between 1 and 5

years. It is important in the interest of safety that

flexible lines are changed at regular intervals.

Inspect for date code stamp and if the line is out

of its guarantee period or shows signs of being

kinked or damaged, replace immediately.