BAST_

02.FM

20

6 Maintenance

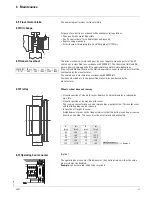

6.8 Hoist motor brake

Check brake at regular intervals

6.8.1 Checking brake

1. Attach rated load

2. Activate brake during lifting and lowering.

Slowing-down paths of up to 10 cm are permissible.

ST05

• Measure distance between fan cover and motor shaft

1. with motor standing still

2. with motor running

The brake displacement is the difference between these two values. If value (S) is

greater than 1.5 mm, the brake must be adjusted. Nominal dimension: 1±0.25 mm.

ST10 - ST60

1. Remove fan cover (1)

2. Remove plug (8)

3. Measure air gap (S) with feeler gauge (F). See table for max. permissible air gap

(S). If the max. permissible air gap (S) has been reached, the brake must be

replaced

• Clean brake (wear a dust protection mask!)

• Check friction surfaces for wear

6.8.2 Adjusting brake

ST05

• Set load down.

Calculate number of shims to be removed. The brake displacement is altered by

0.5 mm per shim.

Example:

Brake displacement measured: 0.8 mm

Remove 2 shims:

-1.0 mm

New brake displacement:

0.8 mm

• Lever off cover (1) with a screwdriver.

• Remove 4 screws (2).

• Pull off brake flange (3).

• Remove number of shims (4) calculated.

• Push on brake flange.

• Reassemble in reverse order.

• Check brake displacement.

Replace brake/slipping clutch unit if all shims have been removed.

Then reset brake displacement.

Caution:

After working on brake, always perform a functional test with rated load.

Hoist motor type

S max.

[mm]

./.E..

1

./.E..-MF

0,6

09.07