Enviro Maintenance Manual 2004

Compressor Maintenance

Do not, at any time lubricate any of the parts with oil, grease, or petroleum products nor clean with acids,

caustics or chlorinated solvents. Be very careful to keep the diaphragm from contacting any petroleum

product of hydrocarbons. It can affect the service life of the pump.

To clean or replace the filters and/or rubber gasket, remove the fi ve screws in the top of the unit. The filters

and gaskets are located beneath this top plate. Remove the filters and wash then in a solvent and/or blow

off with air and replace. The gasket may be cleaned with water. Replace the filters in proper positi on and

replace the gasket. Note that the gasket and top plate will fit in one position only.

To replace the diaphragm, remove the socket cap screws from the head of the pump. The diaphragm is

held in place by two Philip head screws. Remove screws, retainer plate, and diaphragm. The diaphragm

will fit in any position on the connecting rod. Replace the plate and the two Phillips head screws. Torque to

30 inch-pounds on DOA and DAA.

Caution:

Do not raise any burrs or nicks on the heads of these screws. These burrs could cause damage

to the inlet valve.

For replacing the inlet and outlet valve, remove the slotted machine screw that holds each valve in place.

The stainless steel inlet and outlet valves are interchangeable. Clean them with water. When replacing the

outlet valve, place the new valve in location and note there is a retaining bar near the machine screw hole.

This retaining bar holds the valve in position. When replacing the inlet valve, note that the valve holder is

marked with an X in one corner. This X should be in the lower right hand corner toward the inlet of the air

chamber. Replace the head and tighten the socket head screws to 90-100 inch-pounds or torque on DOA

and DAA.

Do not attempt to replace the connecting rod or motor bearings. If after cleaning the unit

and/or installing a new service kit, the unit still does not operate properly, contact your

representative, the factory, or return the pump to one of our authorized Service Centers.

IF YOUR PUMP IS EQUIPPED WITH PLASTIC PLUGS IN THE EXHAUST AND/OR

INTAKE POTS, REMOVE BEFORE STARTING THE UNIT

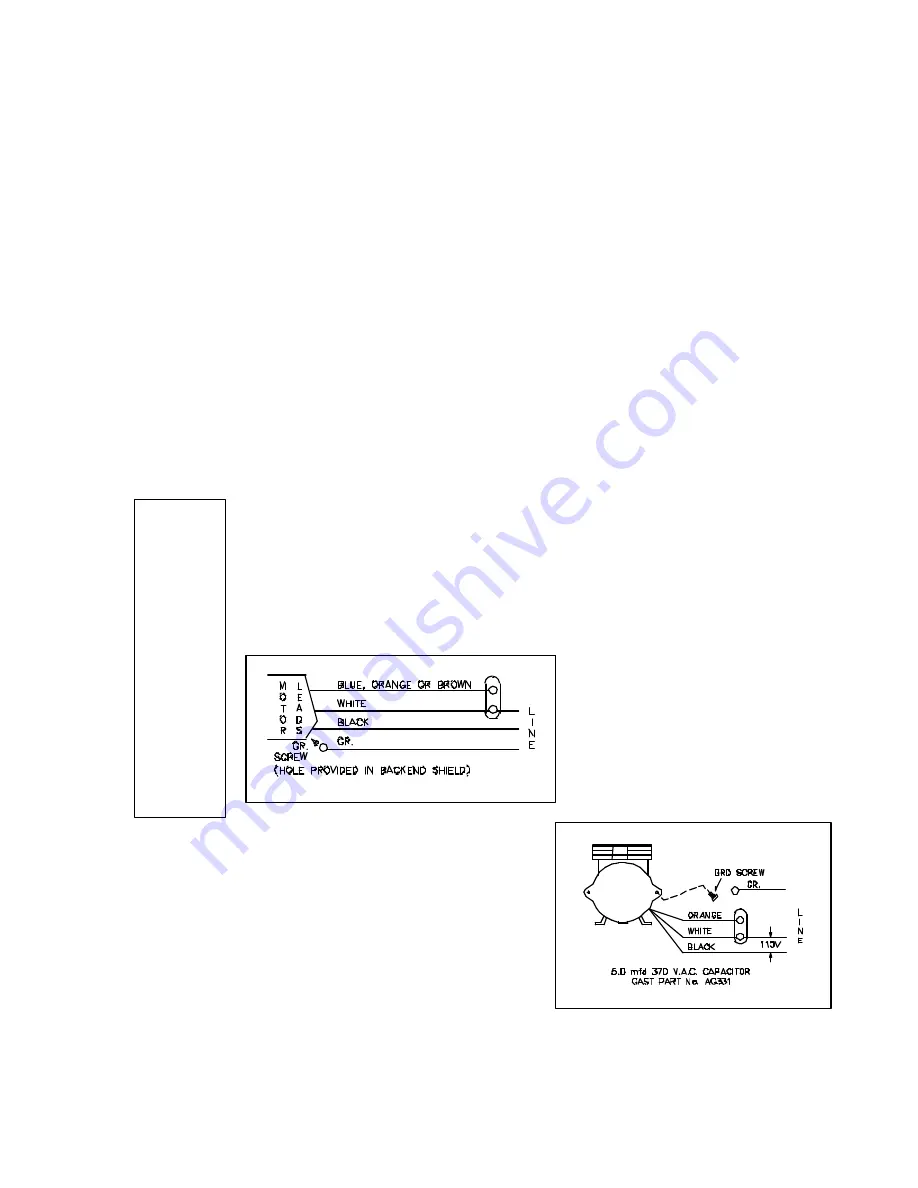

Wiring Information

For any permanent split

capacitor motor, which has four

(4) leads is as follows:

Brown leads to capacitor.

Black-leads to Power Source.

For any permanent split capacitor for DOA & DAA motor,

which has three (3) leads is as follows:

IMPORTANT NOTICE:

DO NOT AT ANY TIME ATTEMPT TO REMOVE THE CONNECTING ROD

OR COMPLETELY DISASSEMBLE THE PUMP. IF IT DOES NOT GIVE

YOU THE PROPER SERVICE EVEN AFTER INSTALLING A NEW

SERVICE KIT, PLEASE RETURN IT TO ONE OF THE AUTHORIZED

SERVICE CENTERS

WARNING -

The motor is

thermally

protected

and can

automaticall

y restart

when the

protector

resets.

ALWAYS

disconnect

KES fan

power

source

before

servicing.

Summary of Contents for KES Enviro

Page 2: ......

Page 4: ......

Page 15: ...Enviro Maintenance Manual 2004 RPD10 Face Plate Figure 19 RPW10 Face Plate Figure 20...