SLS SERIES MANUAL

18

118132-001 RevA

Circuit protection is provided by a front panel fast acting

magnetic trip type circuit breaker. The line input is

connected directly to the line side of the circuit breaker

whereas the load side is connected to the

CONTROL/POWER PWB. The load side of the breaker

is also connected to a step-down type line transformer

which provides voltages for housekeeping and control

circuit power.

LINE VOLTAGE IS PRESENT WHENEVER THE

POWER SUPPLY IS CONNECTED TO EXTERNAL

LINE VOLTAGES. BE SURE TO DISCONNECT

THE LINE CORD BEFORE OPENING THE UNIT.

ALLOW 5 MINUTES FOR INTERNAL

CAPACITANCE TO DISCHARGE BEFORE

REMOVING ANY COVER.

When the circuit breaker is ON, voltage is applied to an

isolated three phase bridge rectifier, which contains the

diodes used for line voltage rectification. The output of

this bridge rectifier is connected to a capacitive filter to

reduce the line related ripple components. The filter

capacitors are initially charged through a resistive inrush

limiter to prevent nuisance tripping of the circuit breaker

during initial turn on.

Approximately 3 seconds after the circuit breaker is

closed, a relay is energized to short the resistive inrush

limiter. This ±150Vdc rail voltage is supplied to the high

frequency inverter.

The DC rails are connected to the high frequency rail

capacitors. These capacitors are high frequency, low loss

type, which provides the energy storage for the high

frequency inverter.

4.3 Inverter

The inverter is a series resonant, series/parallel loaded

topology. A proprietary control scheme is used for

regulating the power generated from the resonant IGBT

inverter. These power devices provide high frequency

switching to control the resonant current flow. The

typical resonant operating period is approximately 10

microseconds. The gate control for the IGBT’s is

provided by the circuitry located on the

CONTROL/POWER PWB. The CONTROL/POWER

PWB also provides circuitry for sensing simultaneous

conduction and overcurrent conditions in the inverter.

4.4 High Voltage Transformer

The output of the Inverter is connected to the primary of

the step up High Voltage Transformer. The High Voltage

Transformer is located in the “stack” assembly beneath

the upper grounded baseplate. The inverter output is

typically an AC high frequency signal about 300 volts in

magnitude. Due to the high frequency, high current

flowing in this cable it is not recommended to try to

modify and/or lengthen the inverter drive cable that

connects the inverter rack and the high voltage stack.

4.5 High Voltage Stack Assembly

The High Voltage Stack Assembly will vary depending

upon the specific model of SLS ordered. The stack is

comprised of an assembly of encapsulated interlocking

high voltage multiplier “wafers”, an encapsulated filter

assembly and an encapsulated voltage feedback divider.

Each encapsulated high voltage multiplier wafer is rated

for 20kV, so an SL160P2000 would use eight (8)

interlocking multiplier wafers to generate the required

output voltage.

The output filter assembly attenuates ripple by virtue of

an R-C type filter. The voltage feedback divider provides

a representative sample of the actual high voltage output

for regulation and monitoring purposes. Current feedback

for regulation and monitoring is provided by a current

sense resistor connected at the low voltage end of the

multiplier stack assembly.

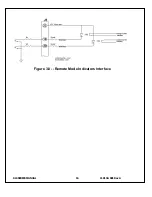

4.6 Control/Power PWB

The majority of control circuits for power supply

operation are located on the CONTROL/POWER PWB.

+15Vdc, -15Vdc, and +10Vdc is generated on the

CONTROL/POWER PWB. High Voltage On/Off control

is accomplished by relay K3, and its associated circuitry.

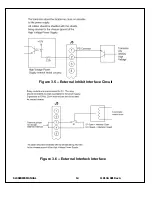

Interlock control is provided by relay K4.

Voltage feedback from the high voltage divider is sent to

the control board via a mass terminated ribbon cable.

Gain adjustment is provided on the HV FDBK PWB.

The KV feedback signal is sent to the front panel DVM

and to the REAR PANEL interface 25 pin D connecter

for remote monitoring. Relay K2 provides switching

between feedback and program signal for the front panel

DVM’s. This allows the user to preset the desired output

before energizing high voltage.

WARNING