SLS SERIES MANUAL

8

118132-001 RevA

NOTE:

The SLS Series is equipped with a slow start

circuit that ramps the output up to its maximum

setting in approximately 6 seconds after the red

HIGH VOLTAGE ON switch is depressed.

K)

To terminate the generation of output power, depress

the green HIGH VOLTAGE OFF switch. In the

HIGH VOLTAGE OFF mode the power supply’s

fault, front panel monitoring and interface circuits are

still active.

L)

To turn off the power supply, turn the circuit breaker

to the off position (0).

NOTE:

If a power supply or system fault occurs, the

unit will revert to the POWER DOWN mode, where

the output power will be turned off. The green HV

OFF lamp will not be illuminated; a red latched fault

should be indicated on the fault diagnostic panel. To

clear and reset the fault, depress the green HV OFF

switch or cycle the AC input power.

AFTER TURN OFF, DO NOT TOUCH ANYTHING

CONNECTED TO THE HV OUTPUT UNTIL THE

CAPACITANCE HAS BEEN DISCHARGED!

LOAD CAPACITANCE MAY BE DISCHARGED BY

SHORTING TO GROUND WITH A SAFETY

DISCHARGE STICK.

THE VOLTMETER ON THE POWER SUPPLY

FRONT PANEL DOES NOT READ THE OUTPUT

VOLTAGE WHEN THE AC LINE POWER IS

TURNED OFF, EVEN IF A CHARGE STILL

EXISTS ON THE LOAD.

ALWAYS OPERATE THE UNIT WITH THE

CHASSIS TOP COVER ON.

A fan maintains safe operating temperature in the inverter

chassis by drawing air over the circuit components. The

cover must be on in order to direct the air flow over the

areas that need cooling. In operation, the unit must be

placed so that the air intake and the fan exhaust are clear

of obstructions.

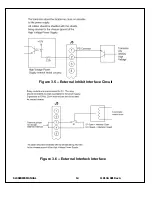

3.2 Standard Features

Whenever possible, electrical isolation should be used

when interfacing with any high voltage power supply.

For power control signals such as EXTERNAL

INTERLOCK, HIGH VOLTAGE OFF, and HIGH

VOLTAGE ON, isolated relay contacts should be used.

For status and control signals such as HIGH VOLTAGE

ON, HIGH VOLTAGE OFF, and EXTERNAL INHIBIT,

etc., opto-isolation should be used. If possible, analog

programming and monitoring signals should be isolated

via analog isolation amplifiers. Spellman application

engineers are available to assist in answering any

questions. All interface cables should be properly

shielded. All power supply signals should be referenced

to the power supplies signal ground on the external

interface connecter.

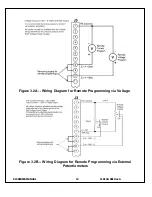

REMOTE PROGRAMMING:

Allows remote

adjustment of the output voltage and current via an

external voltage source. In local control (front panel

control), jumpers are installed on the 25 pin D

external interface connecter J3 at the rear of the

chassis between J3-10 and J3-11 for voltage control

and between J3-8 and J3-9 for current control.

For remote programming, the jumpers are removed and a

positive polarity, ground referenced signal, from 0Vdc to

10Vdc, is applied to the appropriate terminals.

Programming signals should be referenced to J3-1, signal

ground. By adjusting the voltage source from 0Vdc (zero

output) to 10Vdc (full rated output), the desired output

can be selected. See Figure 3.2A on page 13 for the

wiring diagram and specifications.

An alternate method of controlling the output remotely is

by using external resistance, such as a potentiometer or a

resistor network. For remote control the jumpers are

removed and the desired resistor configuration installed.

See Figure 3.2B on page 13 for the wiring diagram.

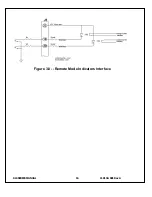

REMOTE MONITOR:

Test points are made

available at the 25 pin D connecter on the rear of the

chassis for monitoring the voltage and current output.

The test points are always positive regardless of the

output polarity where 0Vdc to 10Vdc equals 0 to

100% of the output,

1%. Test points have an output

impedance of 5k ohms. See Figure 3.3 on page 14

for the test point designation.

WARNING

WARNING

CAUTION