4.

Set fence to 90° and near front of jointer,

so amount of exposed cutterhead in front of

fence matches size of desired rabbet.

5.

Start jointer.

6.

Place workpiece firmly against fence and

infeed table.

CAUTION:

To ensure workpiece remains

stable during cut, concave sides of workpiece

must face toward table and fence.

7.

Feed workpiece completely across cutterhead

while keeping it firmly against fence and

tables during entire cut.

CAUTION:

Keep hands at least 4"

away from cutterhead during the entire

cut. Instead of allowing a hand to pass

directly over cutterhead, lift it up and

over cutterhead, and safely reposition it

on the outfeed side to continue supporting

workpiece. Use push blocks whenever

practical to further reduce risk of accidental

hand contact with cutterhead.

8.

Repeat

Step 7 until rabbet is cut to depth.

9.

Re-install cutterhead guard if removed in

Step 3.

DO NOT exceed

1

⁄

8

" cut per pass on this

machine or the risk of kickback and serious

injury will be greatly increased!

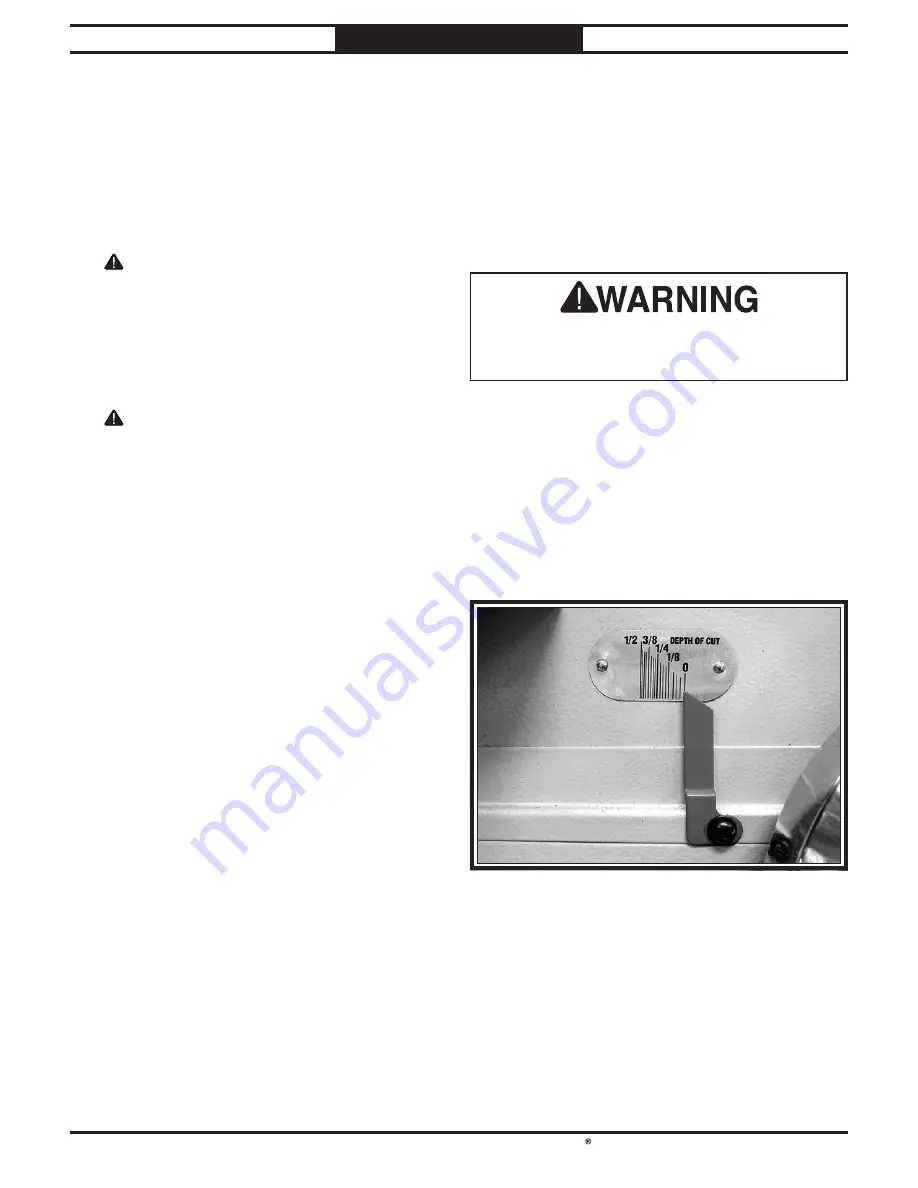

Figure 24. Model SB1091 depth scale.

South Bend Tools

For Machines Mfd. Since 10/20

Model SB1091

-29-

O P E R A T I O N

Setting Depth of Cut

The depth of cut on a jointer affects the amount

of material removed from the bottom of the

workpiece as it passes over the cutterhead.

The depth of cut is set by adjusting the height of

the infeed table relative to the outfeed table and

cutterhead inserts at top dead center (TDC).

To set depth of cut on jointer:

1.

Loosen infeed table lock and rotate

handwheel until depth scale on front of

jointer (see Figure 24) indicates desired

depth of cut.

Note:

The depth scale can be calibrated

or "zeroed" if it is not accurate. (Refer to

Calibrating Infeed Table on Page 40).

2.

Set infeed table positive stops according to

Setting Infeed Table on Page 40.

3.

Tighten infeed table lock before beginning

jointer operations.