-42-

For Machines Mfd. Since 11/21

South Bend Tools

Model SB1125

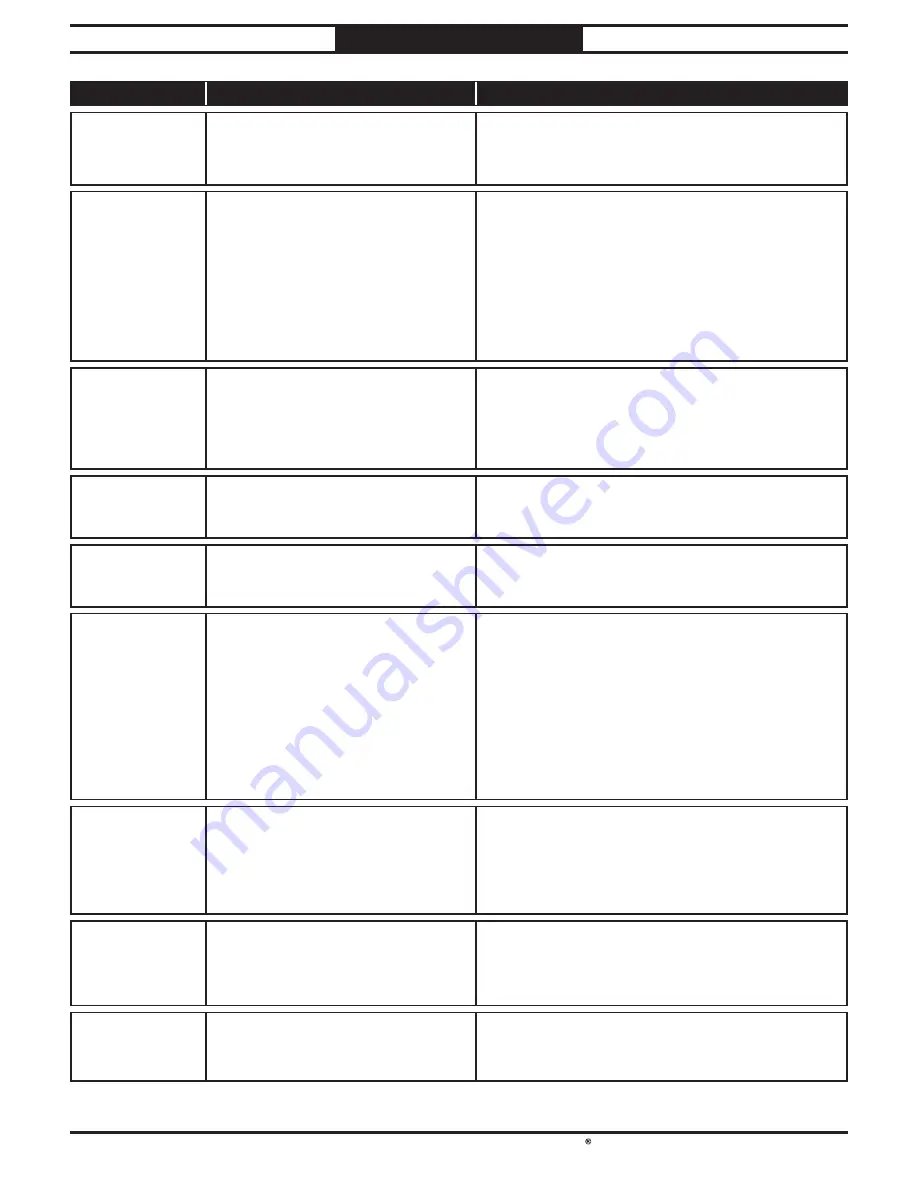

TROUBLESHOOTING

Spindle turns

opposite way of

spindle rotation

switch setting.

1.

Motor connections wired out of

phase.

1.

Swap two incoming motor wires (Page 20).

Breaking tools or

bits/cutters.

1.

Spindle speed/feed rate too fast.

1.

Reduce spindle speed (Page 25)/feed rate.

2.

Taking too big of a cut at one time.

2.

Decrease feed pressure and allow chips to clear.

3.

Improper cutting technique or type

of cut for tool/machine.

3.

Use right technique, tool, or machine for job.

4.

Cutting tool too small.

4.

Use larger cutting tool and slower feed rate.

5.

Cutting tool getting too hot.

5.

Use cutting fluid for appropriate application; reduce

spindle speed (Page 25).

6.

Spindle extended too far down

during or at beginning of operation.

6.

Fully retract spindle and raise table to increase

rigidity.

Symptom

Possible Cause

Possible Solution

Worklight does not

illuminate.

1.

Lens covered with dust.

1.

Clean lens.

2.

Master power switch in OFF (0)

position.

2.

Turn master power switch to ON (1) position.

3.

Bulb burnt out.

3.

Replace bulb (Page 40).

4.

Wiring broken, disconnected, or

corroded.

4.

Fix broken wires or disconnected/corroded

connections.

5.

Worklight switch at fault.

5.

Replace switch.

6.

Worklight at fault.

6.

Replace worklight assembly.

RPM digital

readout does not

work/display is

incorrect.

1.

RPM sensor catching on pulley.

1.

Adjust position/replace if at fault.

2.

Wiring broken, disconnected, or

corroded.

2.

Fix broken wires or disconnected/corroded

connections.

3.

Digital readout circuit board at

fault.

3.

Replace.

Tool/arbor falls out

or loose in spindle.

1.

Debris on tool/arbor or in spindle

taper.

1.

Clean tool/arbor and spindle taper; then re-install

(Page 23).

2.

Excessive feed pressure.

2.

Decrease feed pressure and allow chips to clear.

Workpiece or tool

vibrates or chatters

during operation.

1.

Spindle extended too far down

during or at beginning of operation.

1.

Fully retract spindle and raise table to increase

rigidity.

2.

Table locks not tight.

2.

Tighten table locks.

3.

Workpiece not secure.

3.

Properly clamp workpiece on table.

4.

Spindle speed/feed rate too fast.

4.

Reduce spindle speed (Page 25)/feed rate.

Table hard to

move.

1.

Table locked.

1.

Disengage table locks.

2.

Column dirty/needs lubrication.

2.

Clean/lubricate (Page 33).

3.

Dirty or dry column rack and

pinion.

3.

Clean away chips/debris. Lubricate rack and ball

oilers (Page 34).

Spindle does not

fully retract.

1.

Poorly adjusted return spring.

1.

Increase return spring tension (Page 36).

2.

Debris on spindle/quill rack.

2.

Clean and lubricate spindle/quill rack (Page 34).

3.

Worn return spring.

3.

Replace return spring.

Lack of power at

spindle.

1.

Wrong voltage.

1.

Ensure correct voltage (Page 11).

2.

V-belt(s) worn or loose.

2.

Check belt tension/replace belts with a new

matched set (Page 37).