44

5

Select the data for applying defect correction. To

apply the pixels detected in steps 3 and 4, select 2.

To apply factory settings, select 0. To apply values

that have been saved, select 1.

>DefectPatternLoad=2

6

Turn on defect detection correction.

>AcquisitionStart

>DefectCorrection=1

7

Save the settings. To repeat defect detection

without saving, repeat steps 1 to 6.

>DefectPatternSave

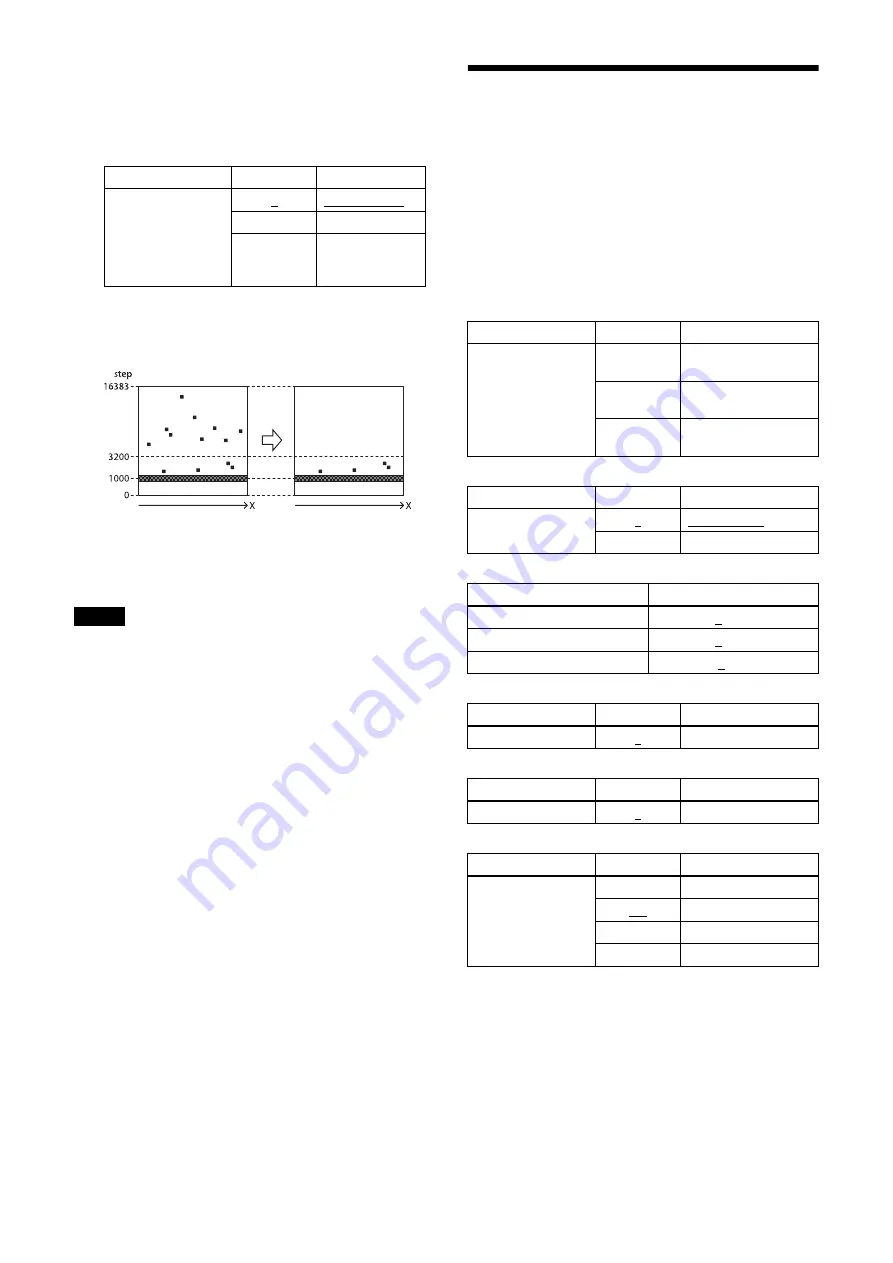

Note

The upper limit of defect detection points is 2047 for

clear and opaque defect points combined. Correction

cannot be performed over the upper limit. The detected

defect points can be confirmed using the

DefectDetectionResult register. If the upper limit is

exceeded, defect detection will fail or abnormal defect

detection will occur, and the DefectDetectionResult

register value will be -1. Perform the defect detection

after the image transfer is set to off.

Shading Correction

Depending on the characteristics of the lens, shadings

caused by a drop in the amount of light around the lens,

or light source variation, are corrected. 35 patterns in

XCG-CG160/CG160C, 20 patterns in XCG-CG240/

CG240C, and 9 patterns in XCG-CG510/CG510C can

be stored as user settings.

Shading Correction has two modes. In peak detection

mode, you can adjust the screen to brightest level. In

average detection mode, you can adjust the whole screen

to its average brightness.

Register

Parameter

Setting

DefectPatternLoad

0

Factory setting

1

User setting

2

Data detected

using DEFECT-

DETECTION

Register

Parameter

Setting

ShadingDetectionMode

0

Check that the

detection is completed

1

Start detection

(peak detection)

2

Start detection

(average detection)

Register

Parameter

Setting

ShadingCorrection

0

Correction off

1

Correction on

ShadingPatternSelect

XCG-CG160/CG160C

0 to 34

XCG-CG240/CG240C

0 to 19

XCG-CG510/CG510C

0 to 8

Register

Parameter

Setting

ShadingPatternSave

1

Save shading patterns

Register

Parameter

Setting

ShadingPatternLoad

1

Read shading patterns

Register

Parameter

Setting

ShadingDetectColor

’R’

RED

’G’

GREEN

’B’

BLUE

’Y’

Brightness