2

PRS-500

TABLE OF CONTENTS

1.

SERVICING NOTE

..................................................

3

2.

GENERAL

...................................................................

5

3.

DISASSEMBLY

3-1.

Disassembly Flow ...........................................................

6

3-2.

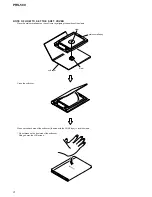

Soft Cover ........................................................................

7

3-3.

B Case Assy .....................................................................

7

3-4.

A Case Assy .....................................................................

8

3-5.

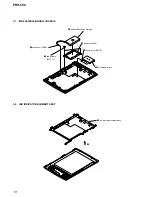

Magnet .............................................................................

9

3-6.

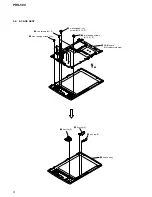

MAIN Board ....................................................................

9

3-7.

MS FLEXIBLE Board, Chassis ...................................... 10

3-8.

Ink Indicator Element Assy ............................................. 10

4.

TEST MODE

............................................................... 11

5.

ELECTRICAL ADJUSTMENT

............................. 12

6.

DIAGRAMS

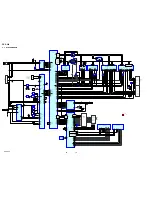

6-1.

Block Diagram ................................................................ 14

6-2.

Printed Wiring Boards

– MAIN, DC Board (Side A) – ........................................ 15

6-3.

Printed Wiring Boards

– MAIN, DC Board (Side B) – ........................................ 16

6-4.

Schematic Diagram – MAIN Board (1/10) – ................. 17

6-5.

Schematic Diagram – MAIN Board (2/10) – ................. 18

6-6.

Schematic Diagram – MAIN Board (3/10) – ................. 19

6-7.

Schematic Diagram – MAIN Board (4/10) – ................. 20

6-8.

Schematic Diagram – MAIN Board (5/10) – ................. 21

6-9.

Schematic Diagram – MAIN Board (6/10) – ................. 22

6-10. Schematic Diagram – MAIN Board (7/10) – ................. 23

6-11. Schematic Diagram – MAIN Board (8/10) – ................. 24

6-12. Schematic Diagram – MAIN Board (9/10) – ................. 25

6-13. Schematic Diagram

– MAIN Board (10/10), DC Board – .............................. 26

7.

EXPLODED VIEWS

7-1.

Overall Assy Section ....................................................... 50

7-2.

A Case Assy Section ........................................................ 51

8.

ELECTRICAL PARTS LIST

.................................. 52

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead-

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

•

Unleaded solder melts at a temperature about 40

°

C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350

°

C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

•

Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

•

Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Flexible Circuit Board Repairing

•

Keep the temperature of the soldering iron around 270

°

C

during repairing.

•

Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

•

Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

•

Never reuse a disconnected chip component.

•

Notice that the minus side of a tantalum capacitor may be

damaged by heat.

• Microsoft, Windows, Windows NT and Windows Media are trademarks or

registered trademarks of Microsoft Corporation in the United States and/or

other countries.

• Adobe and Adobe Reader are trademarks or registered trademarks of Adobe

Systems Incorporated in the United States and/or other countries.

• MPEG Layer-3 audio coding technology and patents licensed from

Fraunhofer IIS and Thomson.

CAUTION

Danger of explosion if battery is incorrectly replaced. Replace

only with the same or equivalent type.