4-48

PDW-700/V1 (E)

CAM CONFIG 2 Display (Setting-2 on camcorder)

Item

Setting

Function

TEST SAW SELECT

REC/SAW

Selects the test signal

COLOR BAR SELECT

ARIB/100%/75%/SMPTE

Selects the color bar type

Reference : The R GAIN and B GAIN value also change accordingly at the

same time.

USER & ALL ONLY

OFF/ON

Show only USER menu in the top menu

RM COMMON MEMORY OFF/ON

Selects whether or not to share settings for when a remote control unit is

connected and when the unit is used alone

RM REC START

RM/CAM/PARA

When an remote control unit is connected, selects which recording start/stop

buttons are enabled

RM :

Remote control unit

CAM :

Camcorder

PARA : Both

SHT DISP MODE

SEC/DEG

Selects shutter speed display (second or degree)

AF MARKER SOURCE

*

1

SAFE/ASPEC/USER

When the FUJINON PF lens (HA22

x

7.4BRD, HA13

x

4.5BRD) is connected,

selects which existing marker is enabled to display the AF detection window

ASPEC : Use ASPECT MARKER as the substitute

SAFE :

Use SAFETY ZONE as the substitute

USER : Use USER BOX as the substitute (It is not displayed in the LCD/

VBS output)

RM F NO DISPLAY

CTRL/RET

Selects the method used to display IRIS F values on the MSU-900 or another

remote control unit

CTRL : Display on the basis of control value from the camera

(normal display method)

RET:

Display on the basis of position information from the lens

(same method as when AUTO IRIS is enabled)

FAN CONTROL

*

2

AUTO/R.MIN/MIN

Selects the control method of the cooling fan

AUTO : The cooling fan rotation is automatically controlled

R.MIN : The cooling fan runs at a low speed only during recording

(The fan stops rotating if the temperature inside the unit does not rise

due to the low temperature environment)

MIN :

The cooling fan runs at a low speed (The fan stops rotating if the

temperature inside the unit does not rise due to the low temperature

environment)

n

Regardless of the setting of this item, the cooling fan starts running at a high

speed if the internal temperature of the unit rises close to the point where an

alarm is issued.

FOCUS MAG SW

MTRY/ALT

Selects the operation when the FOCUS MAG function is assigned to the

ASSIGN switch

MTRY : Turns ON only as long as it is pressed

ALT :

Toggles between ON and OFF each time it is pressed

(Turns OFF automatically after 5 seconds have passed since ON)

*

1 : Displayed only when AF DISPLAY is set to ON on SERVICE MENU.

*

2 : The setting of this item is retained even after the power is turned off.

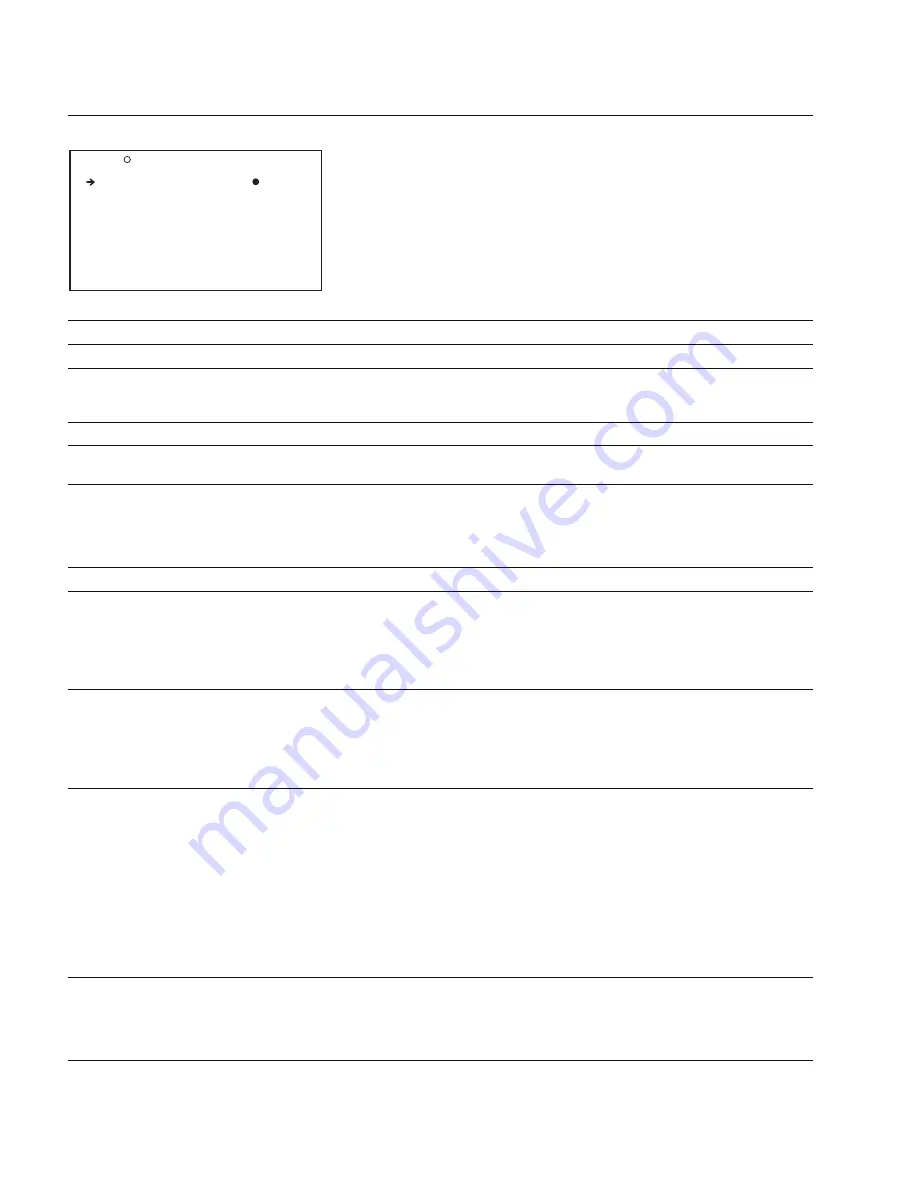

M13 CAM CONFIG 2 TOP

TEST SAW SELECT : SAW

COLOR BAR SELECT: ARIB

USER & ALL ONLY : OFF

RM COMMON MEMORY: OFF

RM REC START : RM

SHT DISP MODE : SEC

AF MARKER SOURCE: ASPEC

RM F NO DISPLAY : CTRL

FAN CONTROL : AUTO

FOCUS MAG SW : MTRY

Summary of Contents for CBK-HD01

Page 10: ......

Page 12: ...1 2 PDW 700 V1 E Optical drive 1 SE 709 2 SE 857 3 SE 858 4 SW 1125G 2 3 1 4 ...

Page 66: ......

Page 230: ......

Page 298: ......

Page 299: ......

Page 300: ...Printed in Japan Sony Corporation 2009 6 16 2008 PDW 700 SY E 9 968 417 03 ...