22

13. Lower plow onto blocking.

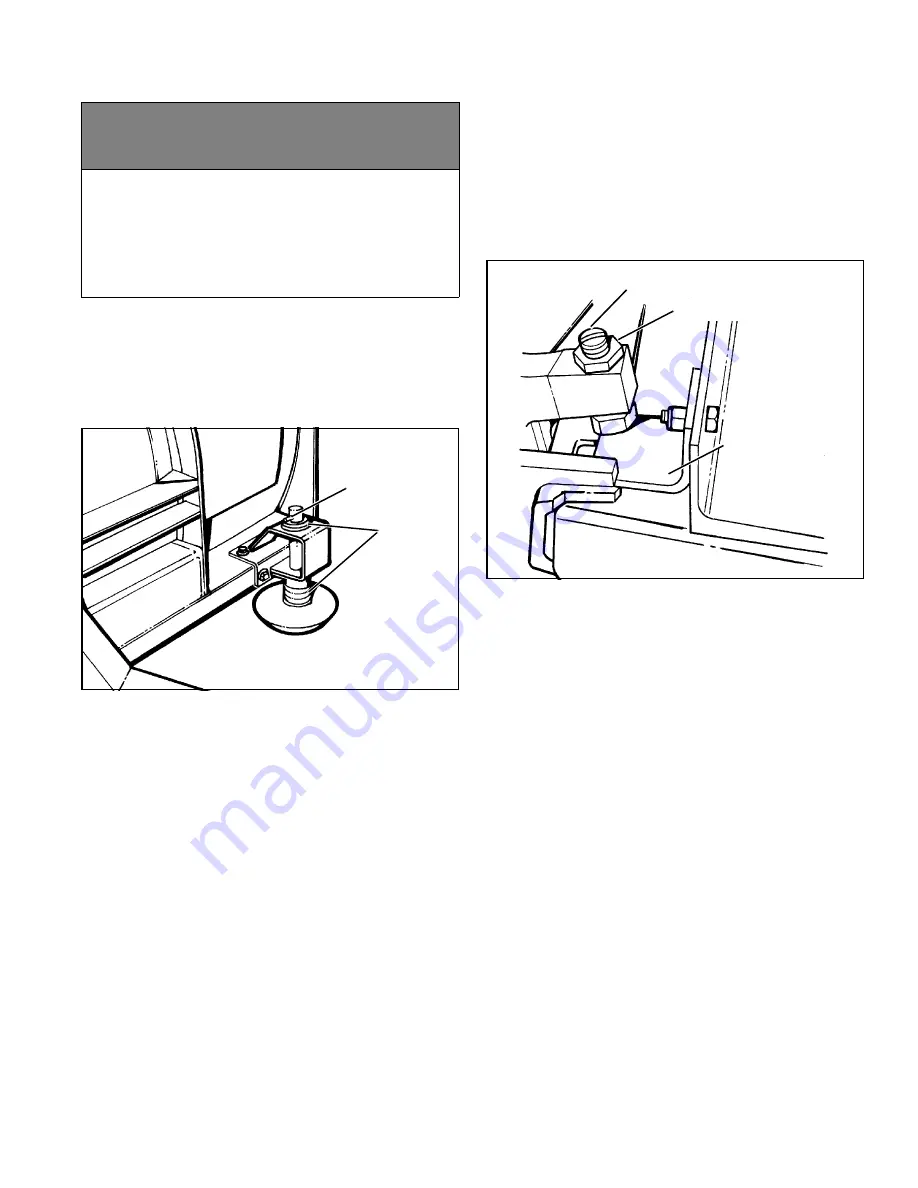

14. Adjust each disk shoe assembly by removing disk

shoe mounting pin and adding or subtracting washers on

the top or bottom of the disk shoe mounting bracket as

required according to measurements taken in step #11

(See Figure 2-17).

Figure 2-17

15. After the disk shoe position is properly adjusted,

place washers on the disk shoe stem - above the disk

shoe mounting bracket, and below the retaining pin - to

remove all up and down movement of the disk shoe in the

bracket. Failure to do this will result in excessive wear of

the holes in the disk shoe mounting bracket and will also

result in bending the stem of the disk shoe.

16. After the wing disk shoe adjustment is complete,

lower the plow to the ground. If this disk shoe adjustment

is correct, the shoes and the wearstrips will all be on the

ground at the same time, if not, repeat steps #11 to #15.

17. Move the wings forward and rearward. If the wing

wearstrips and the center wearstrips are not on the

ground at all times recheck the position of the wing pivot

tubes. The tubes must be vertical, if they are not vertical,

the center disk shoe will need to be adjusted.

Float Limiter Adjustment

IMPORTANT:

The disk shoes must be properly

adjusted prior to adjusting the float limiter. If the

shoes are not properly adjusted, the float limiter

adjustment cannot be properly made.

1. With the vehicle and snow plow on a smooth, level

surface move the wings forward into the “scoop” position

and lower the plow to the ground.

Figure 2-18

2. Loosen the 5/8" jam nut on the top of the float limiter

adjusting screw.

3. Using the screwdriver slot in the top of the float limiter

adjusting screw, turn the adjusting screw down until the

hex head of the adjusting screw touches the surface of

the replaceable wear plate.

4. Turn the adjusting screw up two turns to provide a

gap between the wear plate and the head of the adjusting

screw for proper float allowance.

5. While holding the adjusting screw driver slot, to

prevent turning of the adjusting screw, tighten the 5/8”

jam nut to lock the adjusting screw and prevent turning of

the adjusting screw during operation.

6. Repeat on other side.

c

WARNING

Keep hands and feet clear of wings and center

section when setting blocking and lowering

plow. Moving or falling assemblies could result

in serious injury.

FAILURE TO HEED CAN RESULT IN INJURY

OR DEATH.

WASHERS

PIN

JAM NUT

ADJUSTING SCREW

REPLACEABLE

WEAR PLATE

Summary of Contents for 28V Series

Page 26: ...25 NOTES...

Page 28: ...27 HYDRAULIC SCHEMATIC GRAVITY...

Page 29: ...28 HYDRAULIC SCHEMATIC DOWN PRESSURE...

Page 30: ...29 WIRING SCHEMATIC GRAVITY...