85

Accessories

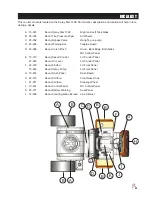

10-417 CHEMICAL CLEAN-LOAD

®

PART LIST

REF#

PART #

DESCRIPTION

QUANTITY

1

HB-38-16-300

Bolt

3

/

8

-16 x 3

1

HNTL-38-16

Flange Lock Nut

3

/

8

-16

1

2

15-816

Mount Bracket

1

3

HBFL-516-18-075

Flange Bolt

5

/

16

-18 x

3

/

4

4

HNFL-516-18

Flange Lock Nut

5

/

16

-18

4

4

15-620

Clean-load Eductor

1

5

18-116

Hose Clamps

4

6

16-156

90° Hose Barb

3

7

18-391

Reducer Coupling

1

8

16-972

Elbow

1

9

8897-80

Hose to Tee by Valve

1

10

8897-35

Hose to fitting on Back of Tank

1

11

16-159

Tank Fitting

1

1. Make sure all chemicals have been flushed out of spray system, as you will be disconnecting fittings

from the pump. Remember to use threaded tape on all new fitting connections.

2. Remove the 1

1

/

4

" plug from the tee on the outlet side of the pump and install one Hose barb (16-156).

Then tighten so it points to the left side of the machine.

3. Install mounting brackets onto left side of center boom

between boom pivot and vertical boom support. Secure

with

3

/

8

x 3 bolt, flat washer (top and bottom) and lock nut.

4. Bolt Clean-load assembly onto mounting bracket using

four flange bolts

5

/

16

-18 x

3

/

4

and flange nuts. Install 90°

hose barb (16-156) into inlet side of Clean-load (valve

with yellow handle) then tighten so it points forward and

down.

5. Install one reducer coupling (18-391) and one 90° Hose

Barb (16-156) onto the outlet side of Clean-load. Tighten

so hose barb points forward and up.

6. Remove plug from top rear center of spray tank and dis

-

card. Install one hose barb (16-159) into tank fitting and

tighten.

7. Route 80" hose from the 90° hose barb on spray pump to the inlet side of the Clean-load and secure

with hose clamps (18-116).

8. Route 35" hose form 90° hose barb on outlet side on Clean-load to the hose barb on the top rear of the

tank.

9. Make sure all hardware, fittings, and clamps are tight. Add about 25 gallons of water to the spray tank.

Start Sprayer and circulate water through system and check for leaks.

10. Be sure to read start up and shutdown instructions for Clean-load assembly before using it with chemi

-

cals. When working with chemicals always wear protective clothing, goggles and gloves.

Summary of Contents for 100684

Page 12: ...10 Diagrams WIRING DIAGRAM Use dielectric grease on all electrical connections ...

Page 14: ...12 Diagrams HYDRAULIC DIAGRAM ...

Page 16: ...14 Parts MAIN BODY DRAWING ...

Page 18: ...16 Parts CONTROL PANEL DRAWING ...

Page 20: ...18 Parts FRONT AXLE DRAWING ...

Page 22: ...20 Parts SEAT CONSOLE AND ROPS DRAWING ...

Page 24: ...22 Parts FUEL TANK DRAWING ...

Page 26: ...24 Parts OIL TANK OIL FILTER OIL COOLER DRAWING ...

Page 28: ...26 Parts FOOT PEDAL LINKAGE DRAWING ...

Page 30: ...28 Parts PUMP DRAWING ...

Page 32: ...30 Parts ENGINE AND SPRAY PUMP DRAWING ...

Page 34: ...32 Parts PARK BRAKE DRAWING ...

Page 36: ...34 Parts REAR AXLE DRAWING ...

Page 38: ...36 Parts TANK DRAWING TURBO QUAD AGITATOR DRAWING ...

Page 40: ...38 Parts 15 301 ORBITROL DRAWING ...

Page 42: ...40 Parts 45 373 DDC20 PISTON PUMP DRAWING ...

Page 53: ...51 Accessories NOTES ...

Page 54: ...52 Accessories 17 835 BOOM DRAWING ...

Page 65: ...63 Accessories NOTES ...

Page 68: ...66 Accessories 16 906 ELECTRIC HOSE REEL DRAWING ...

Page 70: ...68 Accessories 16 129 MANUAL HOSE REEL DRAWING ...

Page 80: ...78 Accessories FOAMER NOZZLE MOUNT HOSE GUARD MOUNT DRAWING ...

Page 82: ...80 Accessories 14 291 FOAMER REPLACEMENT PARTS ...

Page 88: ...86 Accessories 15 620 CHEMICAL CLEAN LOAD DRAWING ...