- 23 -

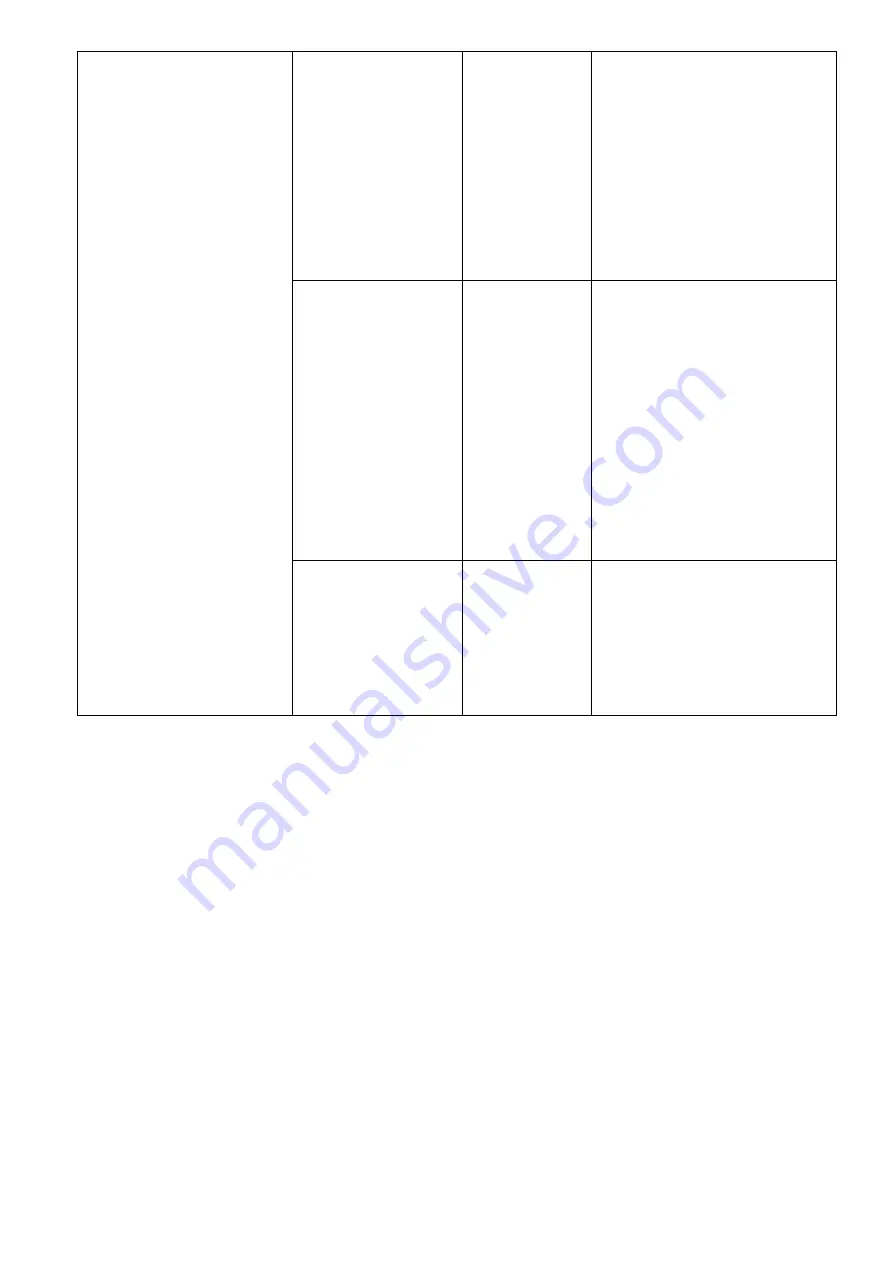

Large overrun. (Stopping

accuracy is low)

Sudden extension of the

rod when the lock is

released.

a. The circuit is not

balanced.

b. Regulator for

balancing pressure

is not adjusted.

c. Line pressure

fluctuates.

d. After stopping

by locking, it is too

fast to unlock.

Change to recommended balanced

circuit. (Refer to Page 13 to 14)

b. Adjust the regulator valve. Check

if the locked status is balanced.

c. Install an air tank so that pressure

fluctuation does not occur when

supplying air to the lock unit and

cylinder.

d. After stopping by locking, release

the lock after waiting for 0.5sec or

longer.

Cylinder speed changed

a. Misalignment of

the piston rod and

guide.

b. High load rate of

the cylinder.

c. Stopping interval

(pitch) is short.

d. Stopping in the

middle of

cushioning

process or

immediately after

the cushioning

process. (When

air cushion type is

used)

e. Line pressure

fluctuates.

a. Adjust the alignment of the piston

rod and guide or use the floating joint.

b. Use a larger cylinder.

c. Set the stop interval to 40mm or

wider.

d. Change the cylinder to rubber

cushion type.

c. Install an air tank so that pressure

fluctuation does not occur when

supplying air to the lock unit and

cylinder.

Changes in the load.

a. Load varies

continuously due

to rotating

movement.

b. Load varies due

to vertical load.

(Step change)

a. Cylinder with lock is not suitable.

Use the cylinder which use

incompressible fluid such as air-hydro

cylinder.

b. When there is a step like change of

the load, use a multi-stage pressure

regulating valve for balancing

pressure.

Summary of Contents for MWB 100 Series

Page 7: ... 7 Selection graph ...