•

The inverter compressor compresses the refrigerant gas and discharges high-

temperature, high-pressure refrigerant gas.

•

In the case of air-cooled refrigeration, the high-temperature, high-pressure refrigerant gas is

cooled down by inverter fan ventilation in the air-cooled condenser, where it is then liquefied.

•

The liquefied high-pressure refrigerant gas expands and its temperature lowers when it

passes through expansion valve A, where it vaporizes after receiving heat from the

circulating fluid in the evaporator.

•

The vaporized refrigerant gas is sucked into the inverter compressor and compressed again.

•

When heating the circulating fluid, the high-pressure, high-temperature refrigerant gas

is bypassed into the evaporator by expansion valve B to heat the circulating fluid.

•

After the circulating fluid discharged from the inverter pump is heated or cooled by

the user’s equipment, it returns to the tank.

•

The circulating fluid is sent to the evaporator by the inverter pump, and is

controlled to a set temperature by the refrigeration circuit, to be discharged to the

user’s equipment side again by the thermo-chiller.

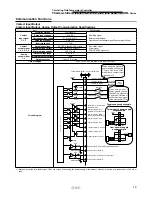

Refrigeration circuit

Circulating fluid circuit

The combination of inverter control of the

compressor and fan, and the precise

control of expansion valves A and B

realizes energy saving operation without

waste and high temperature stability.

Adjusting the

discharge

pressure by

pump inverter

control eliminates

wasteful discharge of

the circulating fluid and

realizes energy saving

operation.

Since the refrigeration circuit is controlled

by the signals from 2 temperature sensors

(for return and discharge), precise

temperature control of the circulating fluid

can be achieved. Therefore, there is no need for a

tank with a large capacity to absorb the circulating

fluid temperature difference, as high temperature

stability can be achieved even with a small-size tank.

This also contributes to space saving.

One compressor controls

2 channels which realize

the independent

temperature control of 2

systems.

Ventilation

Inverter

fan

Inverter

compressor

Inverter

pump

Temperature

sensor

Temperature

sensor

Temperature

sensor

Pump

Expansion valve B

Expansion valve B

Expansion valve A

Expansion valve A

Pump

CH2

CH1

(Optical

system)

(Oscillator)

Temperature of

CH1: Oscillator

and

CH2: Optical system

is controlled individually.

One compressor controls 2 channels.

POINT

POINT

POINT

POINT

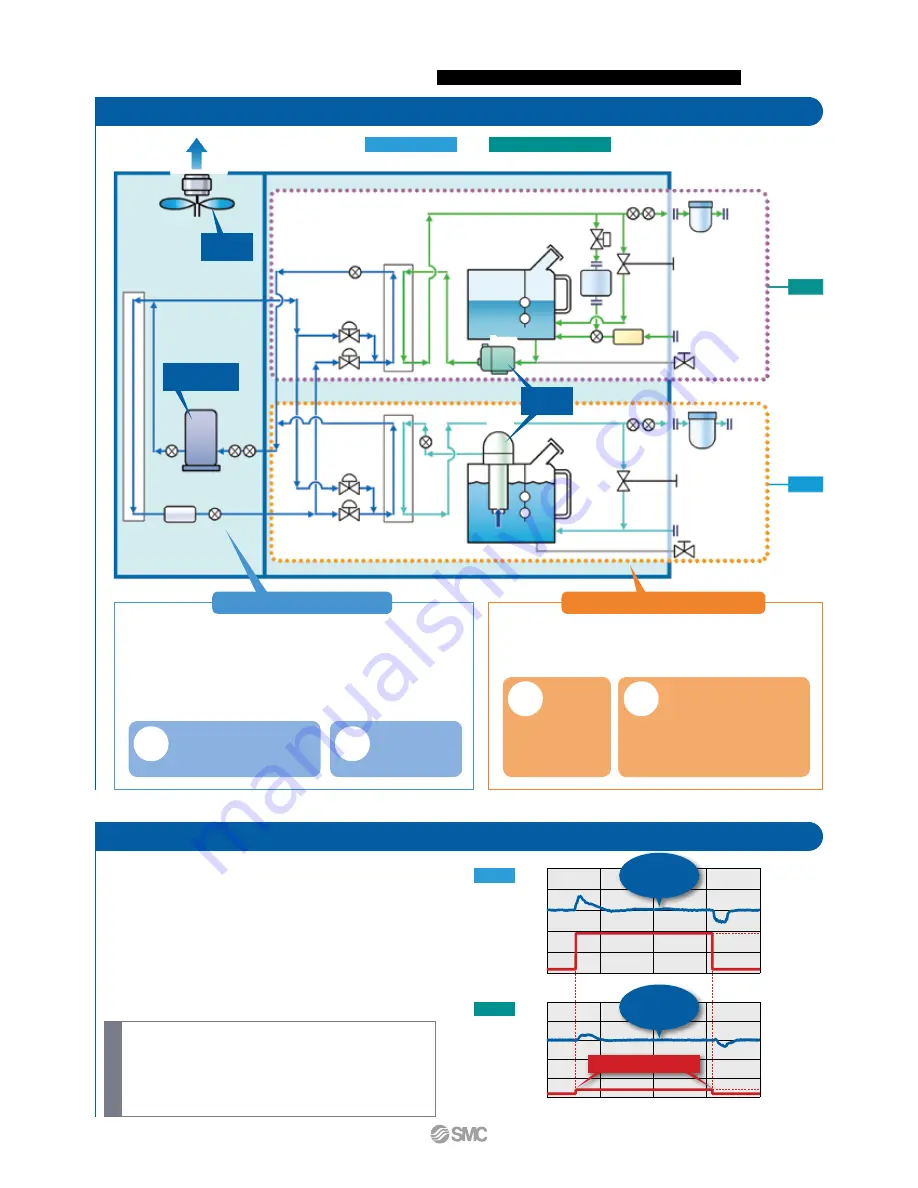

By controlling the inverter compressor, inverter

fan, and electronic expansion valve simultaneous-

ly, it maintains the good temperature stability when

the heat load fluctuates.

•

Outdoor air temperature: 32°C

•

Circulating fluid temperature setting: 20°C/25°C (CH1/CH2)

•

Heat load in the user’s equipment: 26 kW/1 kW (CH1/CH2)

•

Power supply: 200 V 60 Hz

•

Circulating fluid flow rate: 125 LPM/10 LPM (CH1/CH2)

•

External piping: Bypass Heat load

∗

For HRL300-A-20

Temperature stability:

±

0.1

°

C (CH1)

When a load is stable

Pressure sensor

Pressure sensor

Pressure

sensor

Pressure

sensor

Circulating

fluid outlet

Circulating

fluid outlet

Particle filter

Particle filter

Fan

Air-cooled condenser

Compressor

Refrigerant filter

Heat

exchanger

Heat

exchanger

Level

switch

Level

switch

Drain port

Drain port

DI sensor

Circulating fluid

return port

Circulating fluid

return port

Flow

meter

DI filter

Solenoid

valve

Bypass

valve

Bypass

valve

Temperature

sensor

Temperature

sensor

Temperature sensor

Circulating fluid tempe

rature [

°

C]

Circulating fluid tempe

rature [

°

C]

Heat load fluctuation

When a load

is stable

±

0.1

°

C

When a load

is stable

±

0.5

°

C

26 kW load

0 kW load

17

18

19

20

21

22

0

10

20

30

40

1 kW load

0 kW load

22

23

24

25

26

27

0

10

20

30

40

Time [Minute]

CH1

CH2

Conditions

2

Circulating Fluid Temperature Controller

Thermo-chiller

Dual Channel Refrigerated Thermo-chiller for Lasers

HRL

Series