HRL

Series

Dual Channel Refrigerated Thermo-chiller for Lasers

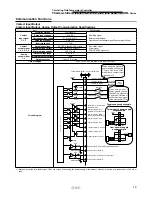

Operation Display Panel

Alarm

Items shown on the touch panel home screen

No.

Classification

CH no.

Item

Explanation

Displayed

value

CH1

Circulating fluid temperature

It indicates the current temperature.

Circulating fluid set temperature

It indicates the set temperature.

Circulating fluid discharge pressure

It indicates the discharge pressure.

Circulating fluid

flow rate

It indicates the fluid flow rate. This value is not measured by a flow meter. It should be used as a

reference value (rough indication). It includes the flow rate in the bypass circuit.

CH2

Circulating fluid temperature

It indicates the current temperature.

Circulating fluid set temperature

It indicates the set temperature.

Circulating fluid discharge pressure

It indicates the discharge pressure.

Circulating fluid

flow rate

It indicates the flow rate measured by a flow meter.

It does not include the flow rate in the bypass circuit.

Circulating fluid electric conductivity

It indicates the electric conductivity.

Common Operating condition display It indicates the run and stop status of the product.

Button

CH1

Independent pump operation

CH1 pump operates independently while the button is pressed.

CH2

Independent pump operation

CH2 pump operates independently while the button is pressed.

Common Operation mode

To select a operation mode from the touch panel (

mode), contact input (

mode),

or serial communication (

mode).

Common Run/Stop

To run/stop the product

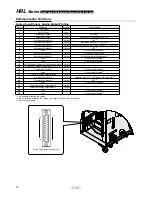

This unit displays 38 types of alarms.

Alarm

code

Indication

Explanation

AL01

CH1 Low Level FL

T

CH1 abno

rmal lo

w tank fluid l

evel

AL02

CH1 Low Level WRN

CH1 lo

w tank fluid l

evel

AL0

3

CH2 Low Level FL

T

CH2 abno

rmal lo

w tank fluid l

evel

AL04

CH2 Low Level WRN

CH2 lo

w tank fluid l

evel

AL06

Fan Inverter

Fan failure

AL09

CH1 High

T

emp. FL

T

CH1 abno

rmal r

ise of circulating fluid tempe

rature

AL10

CH1 High

T

emp.

CH1 circulating fluid tempe

rature rise

AL11

CH1 Low

T

emp.

CH1 circulating fluid tempe

rature drop

AL12

CH1

TEMP REA

DY Alarm

CH1

TEMP REA

DY alarm

AL1

3

CH2 High

T

emp. FL

T

CH2 abno

rmal r

ise in circulating fluid tempe

rature

AL14

CH2 High

T

emp.

CH2 circulating fluid tempe

rature rise

AL15

CH2 Low

T

emp.

CH2 circulating fluid tempe

rature drop

AL16

CH2

TEMP REA

DY Alarm

CH2

TEMP REA

DY alarm

AL17

CH1 HX In High

T

emp. FL

T

CH1 abno

rmal rise in heat exchanger inlet temperature

AL1

8

CH1 Pres

s. Sensor

CH1 f

ailure of circulating fluid discharge pressure sensor

AL19

CH1 High Pres

s.

CH1 circulating fluid discharge pressure

rise

AL20

CH1 Lo

w Pres

s.

CH1 circulating fluid discharge pressure drop

AL21

CH2 Pres

s. Sensor

CH2 f

ailure of circulating fluid discharge pressure sensor

AL22

CH2 High Pres

s. Error

CH2 abno

rmal r

ise in circulating fluid discharge pressure

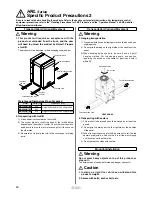

Alarm

code

Indication

Explanation

AL2

3

CH2 High Pres

s.

CH2 circulating fluid discharge pressure

rise

AL24

CH2 Lo

w Pres

s.

CH2 circulating fluid discharge pressure drop

AL25

CH2 Lo

w Pres

s. Error

CH2 abno

r

mal drop in circulating fluid discharge pressure

AL26

CH2 Flow Sensor

CH2 f

ailure of circulating fluid discharge fl

ow sensor

AL27

CH2 High Electric Conductivity

CH2 electric conductivity increase

AL3

0

Digital Input 1

Contact input 1 signal detection

AL3

1

Digital Input 2

Contact input 2 signal detection

AL3

4

Communication

Communication error

AL35

Ambient

T

emp.

Outside of the ambient tempe

rature range

AL3

6

Maintenance

Maintenance ala

rm

AL3

7

Refrigeration Circuit

Compressor circuit failure

AL38

Sensor

Sensor failure

AL39

Controller

Controller failure

AL40

Compressor Inverter

Compressor inverter error

AL41

Compressor Inverter Comm. Compressor inverter communication error

AL42

CH1 Pump I

nverter

CH1 pump inverter error

AL43

CH1 Pump I

nverter Comm. CH1 pump inverter communication error

AL44

CH2 Pump I

nverter

CH2 pump inverter error

AL45

CH2 Pump I

nverter Comm. CH2 pump inverter communication error

15