8

Singer Furtura III series

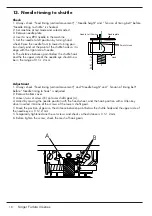

3. Presser foot height and parallelism to the needle plate

Check

1. Lower the feed dog, with the feed dog drop mechanism,so it is below the needle plate.

2. Raise the presser foot to its heighest position.

3. The clearance between the needle plate and the presser foot should be 5.6 mm.

4. Lower the presser foot , it should be parallel to the needle plate slot (B).

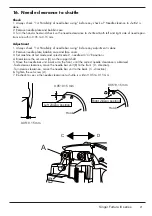

Adjustment

1. Remove the face cover,

2. Lower the feed dog, with the feed dog drop mechanism, so it is below the needle plate.

3. Raise the presser foot to its heighest position.

4. Loosen the set screw (A) and adjust the presser foot height by moving the presser bar up or down.

5. Tighten the set screw (A) securely

6. Lower the presser foot and check so the presser foot is parallel with the needle plate slot (B).

if not

a. Lift up the presser foot

b. Loosen up set screw (A) and adjust the parallelity of the presser foot, by turn the Presser bar to the left

or to the right.

7. Tighten the set screw (A) securely.

8. Re-check height and parallelity of the presser foot.

5.6 mm

B

A