2-52

-

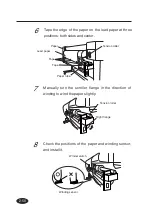

Slacken the paper so that it passes inside the winding

sensor.

-

If the winding unit is not used, turn the winding unit switch

off.

-

When the paper roll for the winding unit nears the diameter

of the winding unit’s flange, remove the winding side paper

roll and replace the paper tube with a new one.

If not so, a winding error may occur.

NOTE

-

When printing without using a winding unit, edge of paper

or printing surface may be damaged or be folded due to

contact with the winding sensor caused by winds.

Fold the winding sensor, or handle the printing surface with

care.

In case that the paper roll for the winding unit

exceeds the diameter of the winding unit’s flange.

•

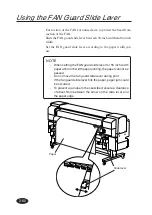

Winding unit switch setting

Either internal winding or external winding can be selected.

When the winding unit is not used, turn the winding unit switch off.

-

Do not change the order of seven tension rollers, as their

outside diameters are different.

Changing the order will cause a skew.

NOTE

Outer winding

Winding unit OFF

Inner winding

Summary of Contents for IP-6600

Page 4: ......