12

SYSTEM TESTS

The completed radio and motor systems can now be powered up,

then tested and adjusted for proper operation. Note that the wing

and propeller are NOT yet installed at this point.

❑

33) Make sure the aileron, elevator, and rudder trim levers on

your transmitter are each in neutral position and that the throttle

stick is in the full "low throttle" position.

a) Turn on your transmitter. NOTE: The transmitter MUST AL-

WAYS be turned on first and turned off last!

b) Plug the battery pack into the ESC. You will hear an audio

tone from the ESC, indicating that is recognizing the signal from

the transmitter.

c) The elevator and rudder servos should now be working. If

necessary, reposition the servo output arms on the elevator and

rudder servos as close to 90

O

to the servo case as possible. Be

sure to reinstall the output arm retaining screws after making the

adjustment.

d) Move the elevator stick on the transmitter to check for the

correct direction of elevator movement. If necessary, use the

servo reversing feature in your transmitter to reverse the direction.

Repeat this same procedure for the rudder servo.

e) With the rudder and elevator servos now moving in the cor-

rect directions, check the neutral positioning of the rudder and el-

evator surfaces. If needed, adjust the V-bend in the pushrods to

properly center these surfaces.

❑

34) Set the wing in place on the fuselage, plugging the aileron

servo chords into the Y-Harness in the fuselage.

a) With the radio on, check the position of the aileron servo

output arms. If necessary, reposition the arms as close to 90

O

to

the servo case as possible. Be sure to reinstall the output arm

retaining screws after making the adjustment.

b) Move the transmitter aileron stick and check for correct di-

rection of aileron movement. If needed, use the servo reversing

feature in the transmitter to reverse the direction.

c) With the aileron servos now moving in the correct direc-

tions, check the neutral position of the ailerons. If needed, adjust

the V-bend in the pushrods to properly align both ailerons in the

neutral position.

❑

35) For safety, the propeller and spinner should NOT be in-

stalled on the motor for this step, which is the first test of the power

system.

a) Slowly advance the throttle stick on the transmitter. The

motor should start turning. If not, perhaps your throttle channel

needs to be reversed on the transmitter. If this is the case, unplug

the flight battery first, and then reverse the throttle direction in your

transmitter. To continue, plug the battery back into the ESC.

b) Again slowly advance the throttle stick. The motor should

begin turning in proportion to the amount of throttle stick move-

ment. Now, make sure the motor shaft is moving in the correct

direction. When viewing the fuselage from the rear to the front -

as if you were sitting in the cockpit - the motor shaft should turn

clockwise, when throttle is applied. If your motor is turning in the

wrong direction, double check that you have the red, black, and

white wires from the motor to the ESC plugged in correctly. If they

are correct (red to red, black to black, white to white), and the

motor still turns the wrong direction, simply switch two of the wires

to change the direction of rotation (make it red to black, and black

to red).

CONTROL SURFACE TRAVEL

❑

36) The maximum distance that a control surface moves when

you move the transmitter stick to full deflection is normally called

the control surface “travel" or “throw”. Most modern radio systems

allow you to adjust the control travel of the servos directly from

the transmitter. This radio feature is usually referred to as EPA

(meaning End Point Adjustment). Use this feature to adjust the

control surface travel for the ailerons, elevator, and rudder of your

RASCAL EP-49. The following control travel measurements are

recommended for your initial test flights of the airplane.

NOTE: Control surface travel measurements are always taken at

the widest part of the control surface, at the trailing edge.

RECOMMENDED CONTROL SURFACE TRAVEL

Ailerons: 5/16" Up - 5/16" Down

Elevator: 3/8" Up - 3/8" Down

Rudder: 1/2" Right - 1/2" Left

COWLING & COOLING

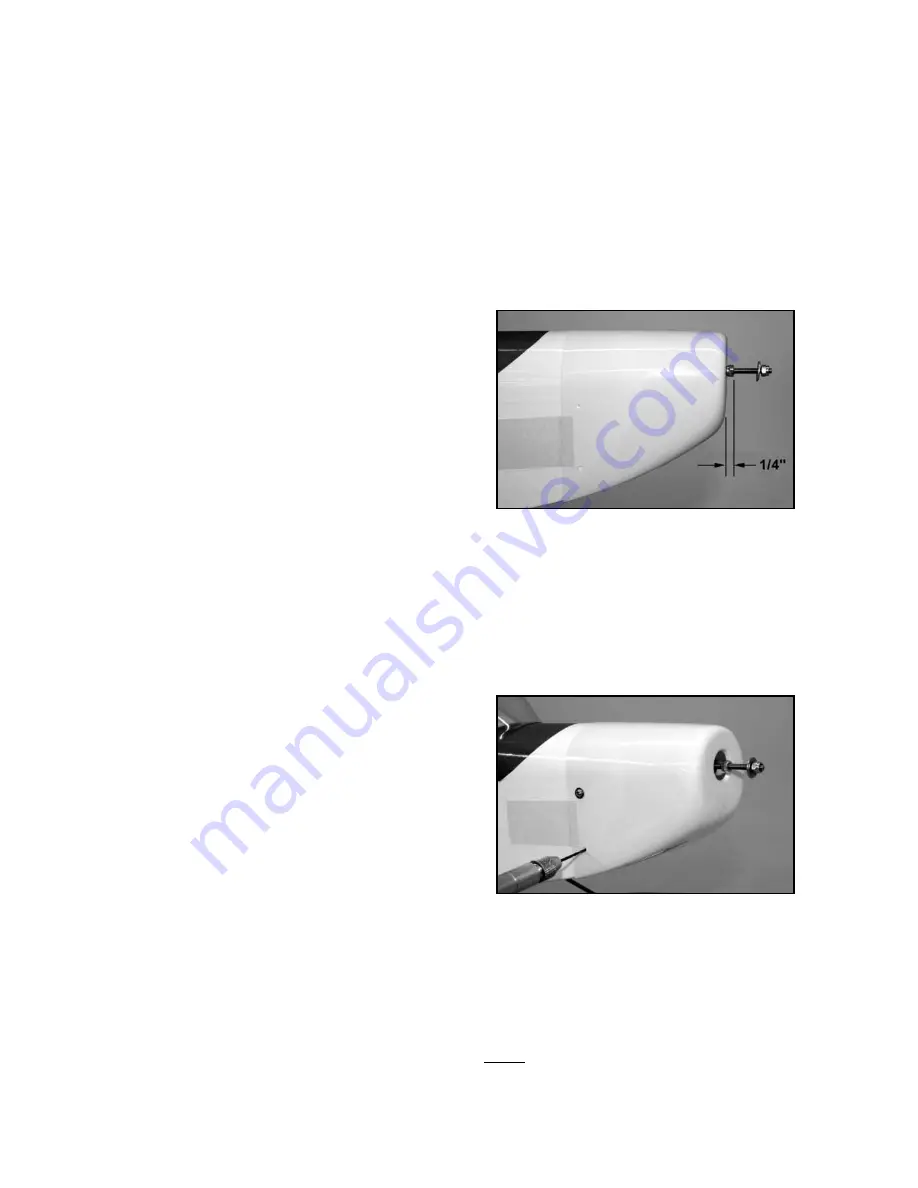

❑

37) From the kit contents, locate the plastic Cowling and (4)

M2 x 6 mm PWA Screws.

a) Slide the cowling in place over the motor and onto the front

of the fuselage. Use pieces of tape to secure the cowling in place,

centered with the motor, with the front of the cowling about 1/4"

behind the front face of the 3.5 mm lock nut on the motor shaft.

b) Use a sharp pencil or a pointed object, such as an awl, to

mark or punch a centered mark in one of the cowl mounting holes.

Use a small (.040") dia. bit to drill a pilot hole through the fuselage

side at the mark just made. Use a screwdriver to install one of

the M2 x 6 mm PWA Screws into the drilled hole.

c. Re-check the placement of the cowling to make sure it hasn’t

shifted, and then again use a sharp object to mark the center of

the opposite cowl mounting hole. Drill a pilot hole and install an-

other mounting screw in this hole.

d. Repeat this process until all four mounting screws are in

place. Then remove the tape.

e) Remove the cowling and harden the holes in the fuselage

side with a drop of Thin CA. Let dry completely.

❑

38) In order to properly cool the motor, ESC, and battery pack

in flight, we need to let some air flow into the cowling. This is done

by making one (or more) holes in the front of the cowling. The

exact shape and location of the hole(s) is not critical. Here are

two different styles of intake air holes that we have used on this

airplane.

Style 1: On one of our prototype models we cut three 1/8" x 1-

1/4" slots in the front slope of the cowling, as shown in the next

two photos. The slots are spaced 3/8" apart. You can use a

Dremel® tool, or a simple hobby knife to make the slots. Finish

the edges of the slots with fine sandpaper.