7 Establishing a connection and diagnostics

08/2008

7.1 Connecting a machine to the HMI

© Siemens AG 2008 All Rights Reserved

7-224

ePS Network Services, Function Manual (FH) - Release 08/2008

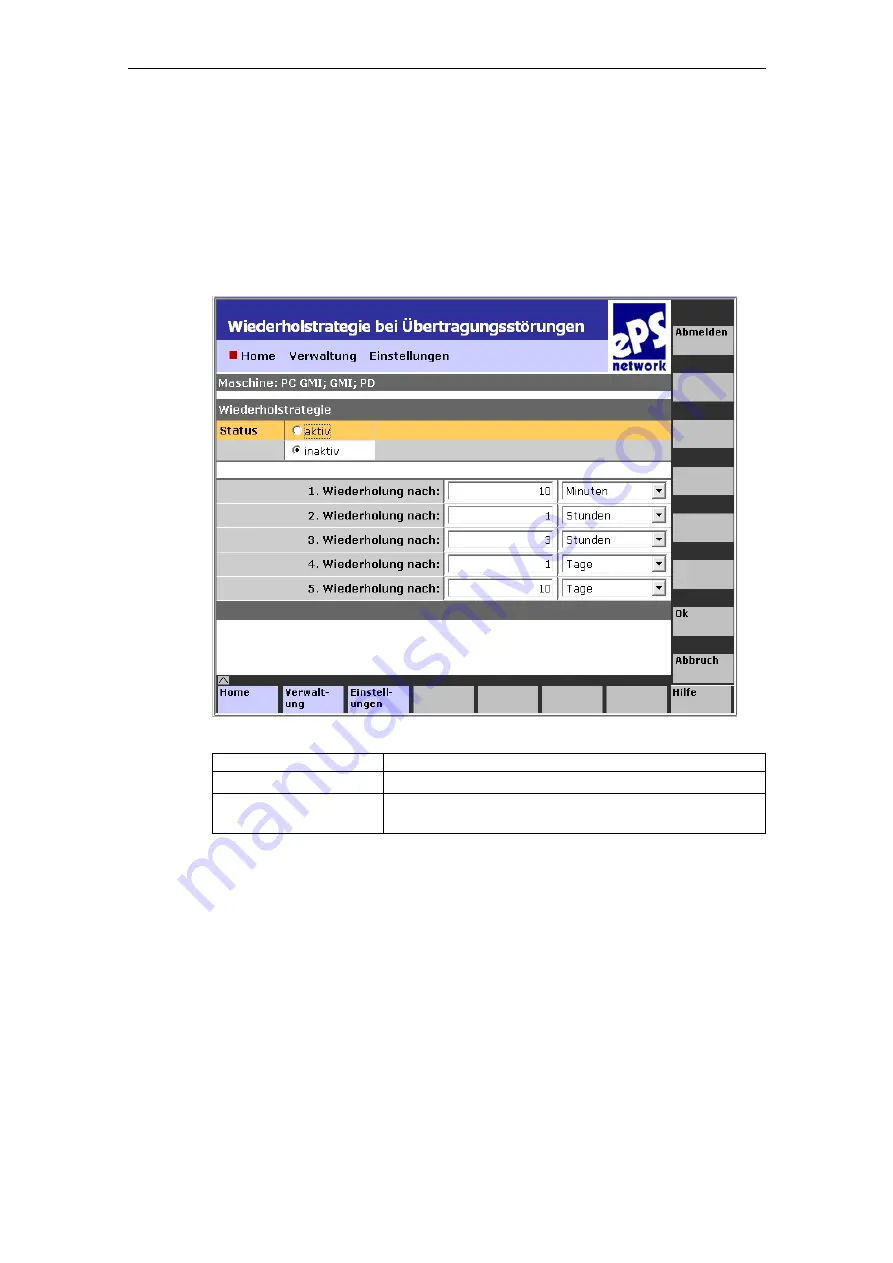

7.1.4 Repetition strategy

Function description

The repetition strategy allows you to define how the ePS client will respond if

communication via the Internet or the ePS Network Server fails. You can activate

and deactivate the repetition strategy and define when the repetition strategy will

be started.

Fig. 7-16: Configuring the repetition strategy on the HMI

Field Content

active/inactive Change

the

status of the repetition strategy

1st - 5th repetition

Time delay after which access to the Internet will be

retried.