13-MAINTENANCE

13.0

SAFETY MEASURES

(See section 3)

Carrying out maintenance and repairs may require to work in dangerous situa-

tions. This machine has been designed making reference to the standards EN292

and EN292/2.

13.1

Tools kit and SPARE parts SUPPLIED WITH THE MACHINE

1

N.1 blade (spare blade for taping unit;

N.1 lower head spring

N.1 upper head spring

N.2 cutter spring

2

Tape threading tool (to feed the tape through the taping unit)

3

Instructions manual of the machine (SMB00055K

)

4

Instructions manual of the taping unit

13.2

NATURE AND FREQUENCY OF MAINTENANCE OPERATIONS

13.3

CHECKS TO BE PERFORMED BEFORE AND AFTER EVERY MAIN-

TENANCE OPERATION

Always set the main switch on

‘0’ (Off) position;

Disconnect the plug from the mains.

During the maintenace operations only the operator performing the main-

tenance must work on the machine.

At the end of every maintenance operation check that all securities and the

safety guards are working properly.

February 2016

43

ENGLISH

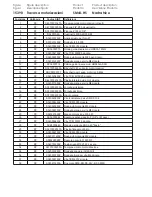

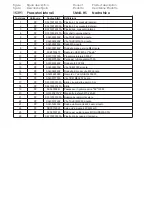

OPERATIONS

FREQUENCY

OPERATORS’ SKILL

CHAPTER

Lubrications

Quarterly

2

13.5-6-7

Top taping head frame inspection brakes

Every two weeks

2

13.2

Blades cleaning

Weekly

2

13.8

Machine cleaning

Wekly

1

12.5

Checkout of safety devices

Daily

1

13.4

Blades replacement

as needed

2

13.9

Belts replacement

as needed

2

13.10

2

1

3

4

Summary of Contents for SM44 HS

Page 15: ...4 PRELIMINARYINFORMATION 4 7 OVERALL DIMENSIONS February 2016 15 ENGLISH ...

Page 52: ......

Page 55: ......

Page 63: ......

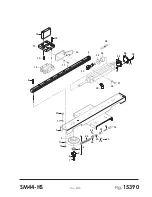

Page 67: ...5 4 3 4 5 6 7 SM44 HS Fig 15395 Sett 2013 ...

Page 68: ......

Page 69: ......

Page 75: ...5 20 4 1 19 17 5 2 3 9 6 5 14 18 19 9 7 11 12 16 15 13 10 8 SM44 HS Fig 15397 Giu 2010 ...

Page 77: ......

Page 84: ......