6

For Installation to the Bicycle, and Maintenance:

•

When securing the brake arm to the frame, be sure to use a brake arm clip that matches the size of the chainstay, and securely

tighten them with the clip screw and clip nut to the specified tightening torque.

Use a lock nut with a nylon insert (self-locking nut) for the clip nut. It is recommended that standard Shimano parts be used for

the clip screw, clip nut and brake arm clip.

If the clip nut comes off the brake arm, or if the clip screw or brake arm clip becomes damaged, the brake arm may rotate on

the chainstay and cause the handlebars to jerk suddenly, or the bicycle wheel may lock and the bicycle may fall over, causing

serious injury.

•

When installing the hub to the frame, be sure to install the correct non-turn washers to the left and right sides, and securely

tighten the hub nuts to the specified torques. If the non-turn washers are installed to one side only, or if the hub nuts are not

tightened sufficiently, the non-turn washer may fall out, which could cause the hub axle to rotate and the cassette joint to

turn. This may then cause the handlebars to be accidentally pulled by the shifting cable, and an extremely serious accident

could result.

< Coaster brake hub >

•

When using a fork end with a rear-facing dropout, use the chain adjusters to remove excess slack from the chain.

CAUTION

Be sure to also inform users of the following:

•

Be sure to shift the shifting lever one gear at a time. During shifting, reduce the force being applied to the pedals. If you try to

force operation of the shifting lever or perform multi-shifting while the pedals are being turned strongly, your feet may come

off the pedals and the bicycle may topple over, which could result in serious injury.

Operating the shifting lever to multi-shift to a light gear may also cause the outer casing to spring out of the shifting lever.

This does not affect the capabilities of the shifting lever because the outer casing returns to the original position after shifting.

•

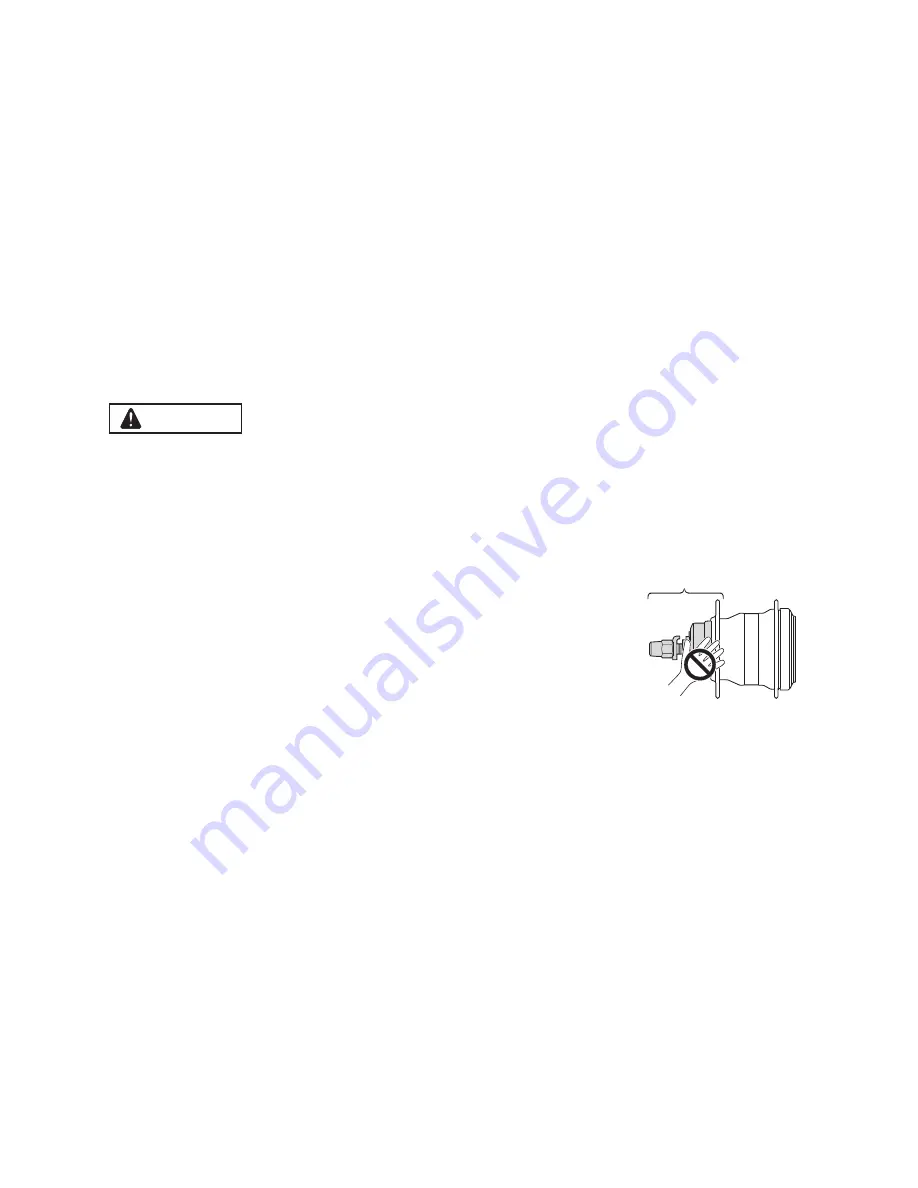

If the brake is used frequently, the area around the brake may become hot. Do not

touch the area around the brake for at least 30 minutes after you finish riding the

bicycle.

Area around the brake

< Coaster brake specifications >

•

Avoid continuous application of the brakes when riding down long slopes, as this will cause the internal brake parts to become

very hot, and this may weaken braking performance. It may also cause a reduction in the amount of brake grease inside the

brake, and this can lead to problems such as abnormally sudden braking.

•

Spin the wheel and confirm that the braking force of the coaster brake is correct.