7

.

Serial Communications Connection Procedure

13

7.2. SHIMADZU Balance Setup

Set up the SHIMADZU Balance.

7.2.1. Parameter Settings

Set parameters for the Balance.

The parameter settings vary depending on the model used.

Use one of the following parameter setting procedures appropriate for your Balance's model.

Model

Procedure to be followed

ATX-R/ATY-R series

1) Parameter settings for ATX-R/ATY-R series

UPX/UPY/UW/UX series

2) Parameter settings for UPX/UPY/UW/UX series

1) Parameter settings for ATX-R/ATY-R series

Set parameters for ATX-R/ATY-R series.

Precautions for Correct Use

Make sure the power supply is OFF before setting up.

If it is ON, the settings described in the following steps and subsequent procedures may not

be applicable.

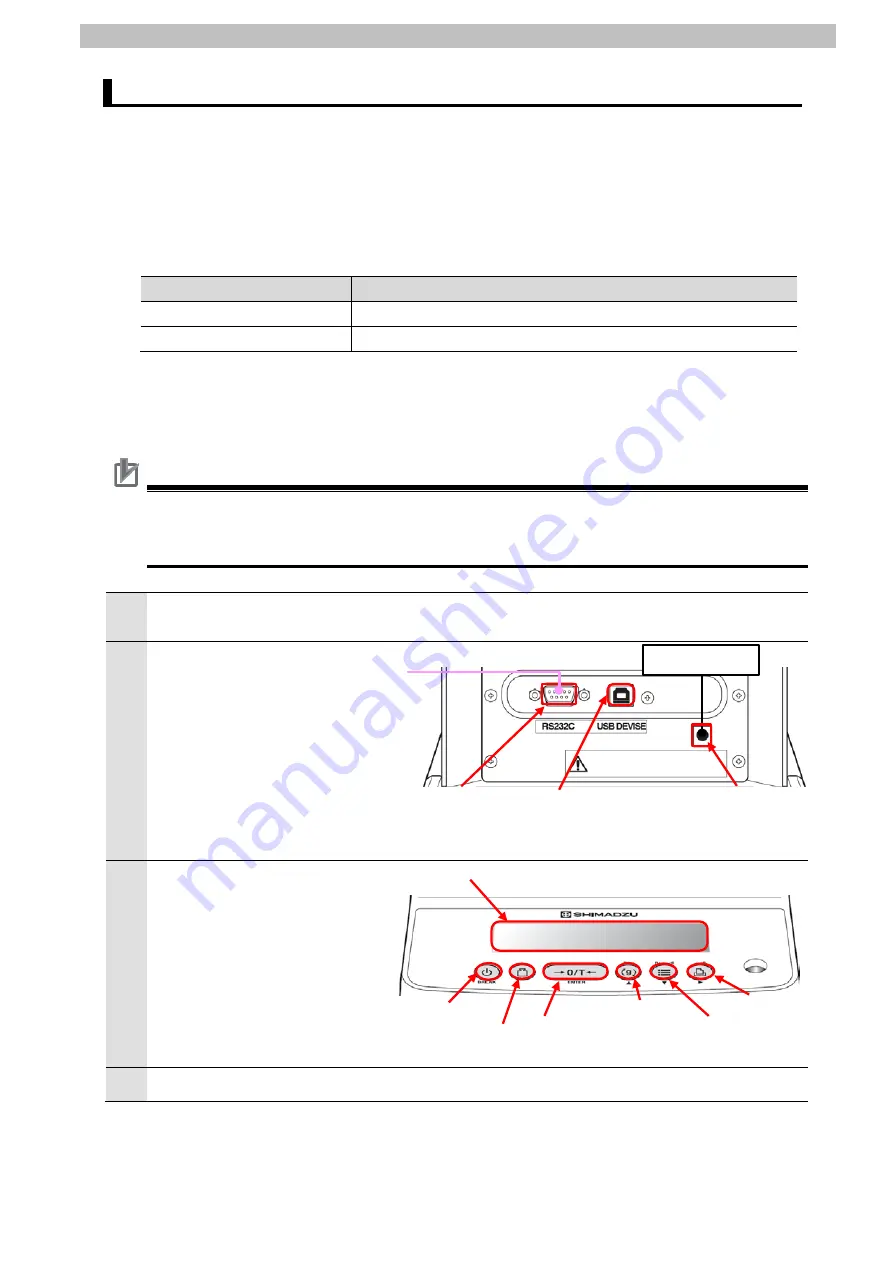

1

Make sure AC Adapter is

powered OFF.

2

Check the position of the

connectors on Balance.

Connect a Serial cable

(RS-232C) to RS-232C

connector.

Connect AC Adapter to DC IN

connector.

Back view of Balance

3

Check the position of the

operation keys by referring to

the figure on the right.

Front view of Balance

4

Turn ON AC Adapter.

Serial cable (RS-232C)

AC adapter

RS-232C connector

O/T key

USB connector

CAL key

DC IN connector

MENU key

PRINT key

UNIT key

Display

panel

BREAK key

Summary of Contents for OMRON CJ Series

Page 82: ...2020 0120 0120 P732 E1 01...