UltraWave Product Guide

Page 43

Verifying the UltraWave alignment

If the UltraWave sensor is encountering detection problems it is possible that one of the unit’s may

be out of alignment. The UltraWave receiver includes a received signal strength indicator (RSSI)

as an alignment aid (LEDs D6 - D13).

1. Remove the lower cover from the receiver unit.

2. Press and hold the tamper switch, while observing the RSSI (LEDs D6 - D13). Do not obstruct

the receiver’s antenna while observing the RSSI.

3. Note the received signal strength (e.g., LED D7 ON).

4. Adjust the horizontal and vertical alignment of the receiver unit slightly to determine if the

received signal can be improved. Recheck the RSSI level.

5. Adjust the horizontal and vertical alignment of the transmitter unit slightly to determine if the

received signal can be improved. Recheck the RSSI level at the receiver unit.

6. Once the alignment is complete, connect the UCM and select the Recalibrate button.

7. Replace the lower cover on the receiver unit.

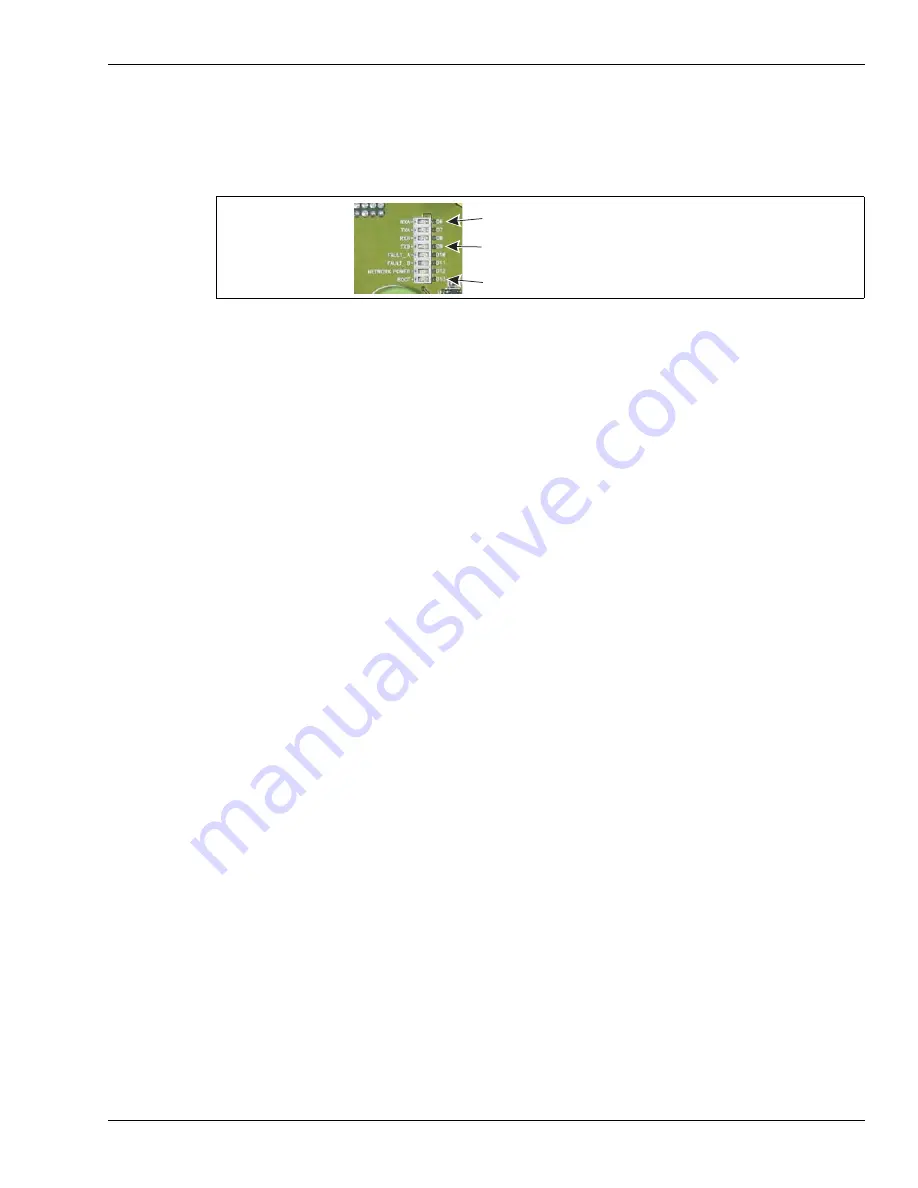

Figure 34 LEDs D6 - D13 RSSI alignment aid

D6 - maximum received signal strength

D13 - minimum received signal strength

D9 - minimum operational signal strength

(operational range D9 to D6)