8-ENG

D22235

Break-In Procedures

This procedure is only required the first time the air

compressor is put into service.

1. Set the pressure switch OFF/AUTO lever to the "OFF"

position.

2. Plug the power cord into the correct branch circuit

receptacle.

3. Turn the regulator clockwise, opening it fully, to

prevent air pressure build-up in the tank.

4. Move the OFF/AUTO lever to "AUTO". The compres-

sor will start.

5. Run the compressor for 15 minutes. Make sure the

regulator is open and there is no tank pressure build-

up.

6. After 15 minutes, close the regulator by turning it

counterclockwise. The air tank will fill to cut-out

pressure and then the motor will stop.

Refer to Operating Procedures.

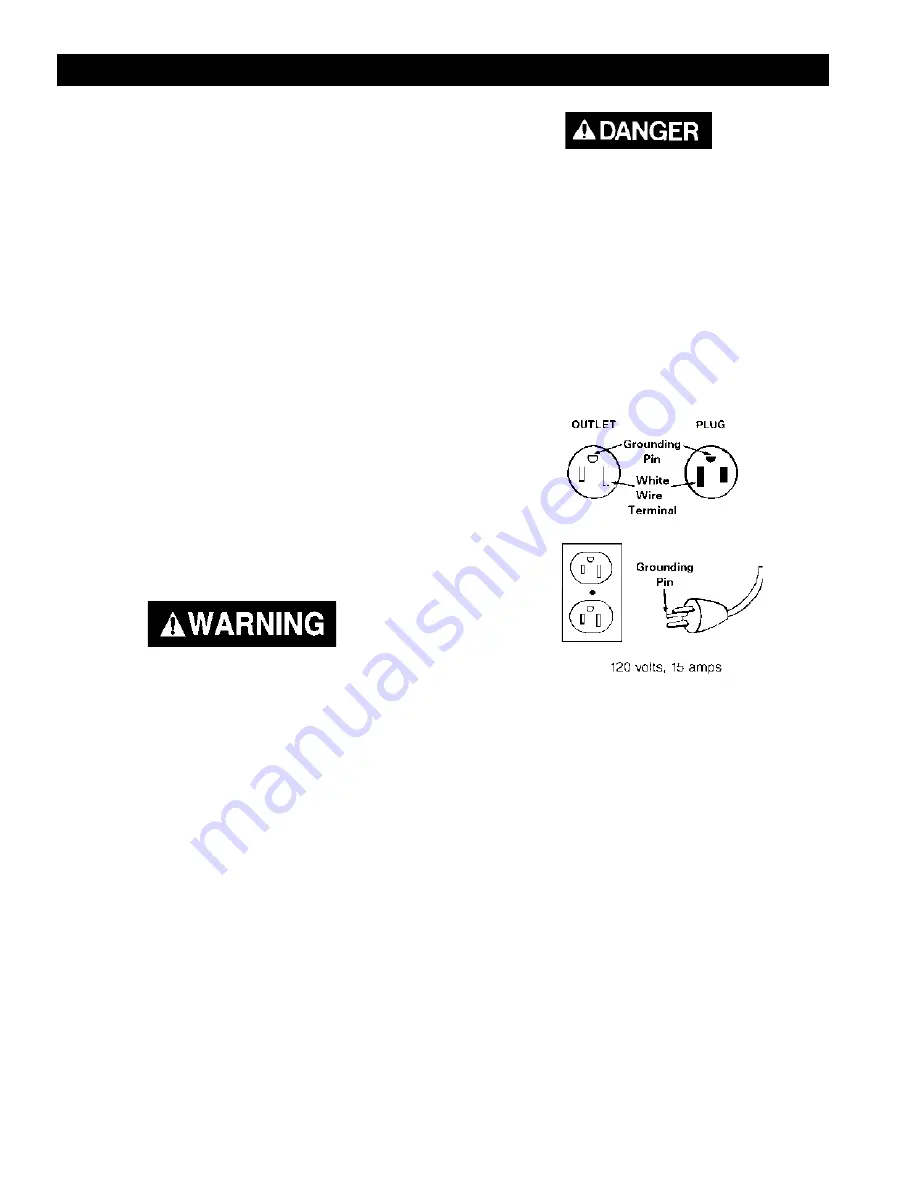

RISK OF ELECTRICAL SHOCK. IF REPAIR-

ING OR REPLACING CORD OR PLUG, THE

GROUNDING WIRE MUST BE KEPT SEPA-

RATE FROM THE CURRENT-CARRYING

WIRES. NEVER CONNECT THE GROUNDING

WIRE TO A FLAT BLADE PLUG TERMINAL.

(THE GROUNDING WIRE HAS INSULATION

WITH AN OUTER SURFACE THAT IS GREEN

- WITH OR WITHOUT YELLOW STRIPES.)

If these grounding instructions are not completely under-

stood, or if in doubt as to whether the compressor is

properly grounded, have the installation checked by a

qualified electrician.

Location of the Air Compressor

Locate the air compressor in a clean, dry and well venti-

lated area. The air filter must be kept clear of obstructions

which could reduce air delivery of the air compressor. The

air compressor should be located at least 12" away from

the wall or other obstructions that will interfere with the

flow of air. The air compressor head and shroud are

designed to allow for proper cooling. If humidity is high, an

air filter can be installed to remove excessive moisture.

Follow the instructions packaged with the air filter for

proper installation.

Extension Cords

Use extra air hose instead of an extension cord to avoid

voltage drop and power loss to the motor.

If an extension cord

must

be used, be sure it is:

•

a 3-wire extension cord that has a 3-blade grounding

plug and a 3-slot receptacle that will accept the plug

on the product.

•

in good condition.

•

no longer than 50 feet.

•

12 gauge (AWG) or larger. (Wire size increases as

gauge number decreases. 10 AWG and 8 AWG may

also be used. DO NOT USE 14 or 16 AWG.)

Grounding Instructions

IMPROPER GROUNDING CAN RESULT IN

ELECTRICAL SHOCK. IN THE EVENT OF A

SHORT CIRCUIT, GROUNDING REDUCES

THE RISK OF SHOCK BY PROVIDING AN

ESCAPE WIRE FOR THE ELECTRIC CUR-

RENT. THIS AIR COMPRESSOR MUST BE

PROPERLY GROUNDED.

1. The air compressor is equipped with a cord having a

grounding wire with an appropriate grounding plug.

The plug must be used with an outlet that has been

installed and grounded in accordance with all local

codes and ordinances. The outlet must have the

same configuration as the plug. DO NOT USE AN

ADAPTER.

2. Do not modify the plug that has been provided. If it

does not fit the available outlet, the correct outlet

should be installed by a qualified electrician.

3. Inspect the plug and cord before each use. Do not

use if there are signs of damage.

INSTALLATION & BREAK-IN PROCEDURES

Summary of Contents for TURBO HOT DOG DAC-7128-2

Page 13: ...13 ENG D22235 REPAIR PARTS...

Page 14: ...14 ENG D22235 AIR COMPRESSOR DIAGRAM...

Page 31: ...13 FR D22235 LISTE DE PI CES...