7-ENG

D22235

Air Compressor Pump:

To compress air, the piston

moves up and down in the cylinder. On the downstroke,

air is drawn in through the air intake valves. The exhaust

valve remains closed. On the upstroke of the piston, air is

compressed. The intake valves close and compressed

air is forced out through the exhaust valve, through the

outlet tube, through the check valve and into the air tank.

Working air is not available until the compressor has

raised the air tank pressure above that required at the air

outlet.

Check Valve:

When the air compressor is operating, the

check valve is "open", allowing compressed air to enter

the air tank. When the air compressor reaches "cut-out"

pressure, the check valve "closes", allowing air pressure

to remain inside the air tank.

Pressure Release Valve:

The pressure release valve

located on the side of the pressure switch, is designed to

automatically release compressed air from the compres-

sor head and the outlet tube when the air compressor

reaches "cut-out" pressure or is shut off. If the air is not

released, the motor will try to start but will be unable to.

The pressure release valve allows the motor to restart

freely. When the motor stops running, air will be heard

escaping from the valve for a few seconds. No air should

be heard leaking when the motor is running.

Pressure Switch:

The pressure switch automatically

starts the motor when the air tank pressure drops below

the factory set "cut-in" pressure. It stops the motor when

the air tank pressure reaches the factory set "cut-out"

pressure.

Safety Valve:

If the pressure switch does not shut off the

air compressor at its cut-out pressure setting, the safety

valve will protect against high pressure by "popping off"

at its pre-set pressure.

Regulator:

The air pressure coming from the air tank is

controlled by the regulator knob. Turn the knob clockwise

to increase pressure and counterclockwise to decrease

pressure. To avoid minor readjustment after making a

change in pressure setting, always approach the desired

pressure from a lower pressure. When reducing from a

higher to a lower setting, first reduce to some pressure

less than that desired, then bring up to the desired

pressure. Depending on the air requirements of each

particular accessory, the outlet regulated air pressure

may have to be adjusted while operating the accessory.

Outlet Pressure Gauge:

The outlet pressure gauge

indicates the air pressure available at the outlet side of the

regulator. This pressure is controlled by the regulator and

is always less or equal to the tank pressure. See "Oper-

ating Procedures."

Tank Pressure Gauge:

The tank pressure gauge indi-

cates the reserve air pressure in the tank.

You have purchased an air compressor unit consisting of a 1 cylinder, single-stage air compressor pump, an air tank

and associated controls.

This air compressor requires no oil. Now you can enjoy all the benefits of having an air compressor without ever having

to purchase, add or change oil.

Separate air transformers which combine the functions of air regulation and/or moisture and dirt removal should be used

where applicable.

GENERAL INFORMATION

DESCRIPTION OF OPERATION

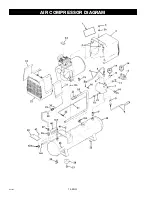

Summary of Contents for TURBO HOT DOG DAC-7128-2

Page 13: ...13 ENG D22235 REPAIR PARTS...

Page 14: ...14 ENG D22235 AIR COMPRESSOR DIAGRAM...

Page 31: ...13 FR D22235 LISTE DE PI CES...