Latest products and information available at www.sealite.com

5

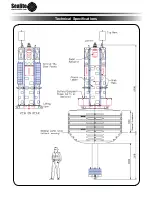

TRIDENT-3000-HEX with hexagonal aluminium tower

3000mm dia. Ocean Buoy

TRIDENT-3000-HEX Ocean Buoy

The TRIDENT-3000 is one of the largest rotationally moulded buoys available, with a float

diameter of 3 meters and lantern focal height of up to 5 meters.

The float section of the Trident-3000 is built from four (4) roto-moulded quadrants, which

fasten together to form an incredibly robust 3 meter wide float section standing 1.8m tall. Each

quadrant is moulded from UV-stabilised virgin polyethylene, and has an 18mm wall thickness.

The hexagonal tower design provides a large, robust superstructure and is built from marine

grade aluminium subject to powder-coating in high visibility colours. The tower is capable of

supporting additional payload.

Number of Lifting Points = 4

SWL for 2 or more lifting points = 8630kg (mooring point)

Visual area = 7.1m

2

(with daymark)

SWL for 1 point lifting = 6000kg (deck and primary structure)

Estimated roll period (bare) = 2.2sec

Estimated roll period (moored) = 1.6sec

SPECIFICATIONS

Refer to website www.sealite.com

Summary of Contents for TRIDENT-3000-HEX

Page 2: ...Technical Specifications ...