Section 03

ENGINE

Sub-Section 07

(ROTARY VALVE)

03-07-2

GENERAL

The following verification procedures such as

clearance of rotary valve cover or rotary valve

shaft gear backlash can be performed without re-

moving engine from watercraft.

However engine must be removed from water-

craft to work on rotary valve shaft/components.

Refer to ENGINE 03-03 for engine removal proce-

dure.

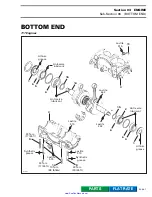

Bottom end must be opened to remove rotary

valve shaft. Refer to ENGINE 03-06.

INSPECTION ON WATERCRAFT

Remove carburetor(s). Refer to FUEL SYSTEM

05-04.

NOTE:

On the 717D engine (SP model), rotary

valve cover and carburetor are removed as an as-

sembly.

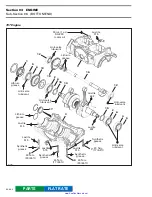

1, Rotary Valve Cover

Unscrew 4 screws

no. 2

and withdraw rotary

valve cover and valve

no. 13

.

Rotary Valve/Cover Clearance

The clearance between the rotary valve and the

cover must be 0.30

±

0.05 mm (.012

±

.002 in).

NOTE:

If the clearance is below 0.25 mm (.010 in)

this could create an overheating situation and if

the clearance is over 0.35 mm (.014 in) this could

create a hard starting situation.

There is two methods to verify rotary valve

/cover clearance. One with a 45

°

feeler gauge, the

other one with a solder.

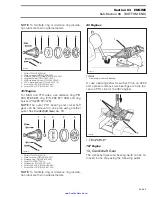

45

°

FEELER GAUGE METHOD

Remove O-ring from rotary valve cover.

Remove intake manifold from rotary valve cover

(except 787 engine).

Reinstall cover in place WITHOUT its O-ring and

torque screws to 20 N•m (15 lbf•ft).

Feeler gauge blade from 0.25 mm (.010 in) to 0.35

mm (.014 in) thickness should fit between rotary

valve and cover.

Insert feeler gauge blade through cover inlet ports

to verify clearance. At least verify clearance at two

different places in each port.

1. 45

°

feeler gauge

If rotary valve cover clearance is out of specifica-

tion, machine rotary valve cover seating surface

or replace the cover.

SOLDER METHOD

Remove O-ring from rotary valve cover.

Use the following type of solder:

– rosin core

– diameter:

0.8 mm (.032 in)

– electronic application (available at electronic

stores)

Install two solder pieces of 13 mm (1/2 in) long

directly on rotary valve, one above and one below

rotary valve gear. Apply grease to hold solder in

position.

Reinstall cover in place WITHOUT its O-ring and

torque screws to 20 N•m (15 lbf•ft).

Remove cover then clean and measure compressed

solder thickness, it must be within the specified tol-

erance 0.30

±

0.05 mm (.012

±

.002 in).

F01D53A

1

www.SeaDooManuals.net

Summary of Contents for 1997 GSI

Page 1: ...www SeaDooManuals net ...

Page 2: ...0 0 SHOP MANUAL 0 219 100 048 www SeaDooManuals net ...

Page 343: ...www SeaDooManuals net ...

Page 344: ...www SeaDooManuals net ...

Page 345: ...www SeaDooManuals net ...

Page 346: ...www SeaDooManuals net ...

Page 347: ...www SeaDooManuals net ...

Page 348: ...www SeaDooManuals net ...

Page 349: ...www SeaDooManuals net ...

Page 350: ...www SeaDooManuals net ...

Page 351: ...www SeaDooManuals net ...

Page 352: ...www SeaDooManuals net ...

Page 353: ...www SeaDooManuals net ...

Page 354: ...www SeaDooManuals net ...

Page 355: ...www SeaDooManuals net ...

Page 356: ...www SeaDooManuals net ...

Page 357: ...www SeaDooManuals net ...

Page 358: ...www SeaDooManuals net ...

Page 359: ...www SeaDooManuals net ...

Page 360: ...www SeaDooManuals net ...

Page 361: ...www SeaDooManuals net ...

Page 362: ...www SeaDooManuals net ...

Page 363: ...www SeaDooManuals net ...

Page 364: ...www SeaDooManuals net ...

Page 365: ...www SeaDooManuals net ...

Page 366: ...www SeaDooManuals net ...

Page 367: ...www SeaDooManuals net ...

Page 368: ...www SeaDooManuals net ...

Page 369: ...www SeaDooManuals net ...

Page 370: ...www SeaDooManuals net ...

Page 371: ...www SeaDooManuals net ...

Page 372: ...www SeaDooManuals net ...