Configuring the Test Station Software Parameters

37

SCOTT SAFETY

087-0048 REV B

After configuration changes, click WRITE. If a successful write, a Green Bar appears

in the bottom right hand corner of the screen.

details the parameters. These

parameters allow you to configure each sensor type to met your needs. Once this

configuration has been sent to the Test Station, every monitor that is Bump Tested

takes on these new configuration parameters.

Table 13

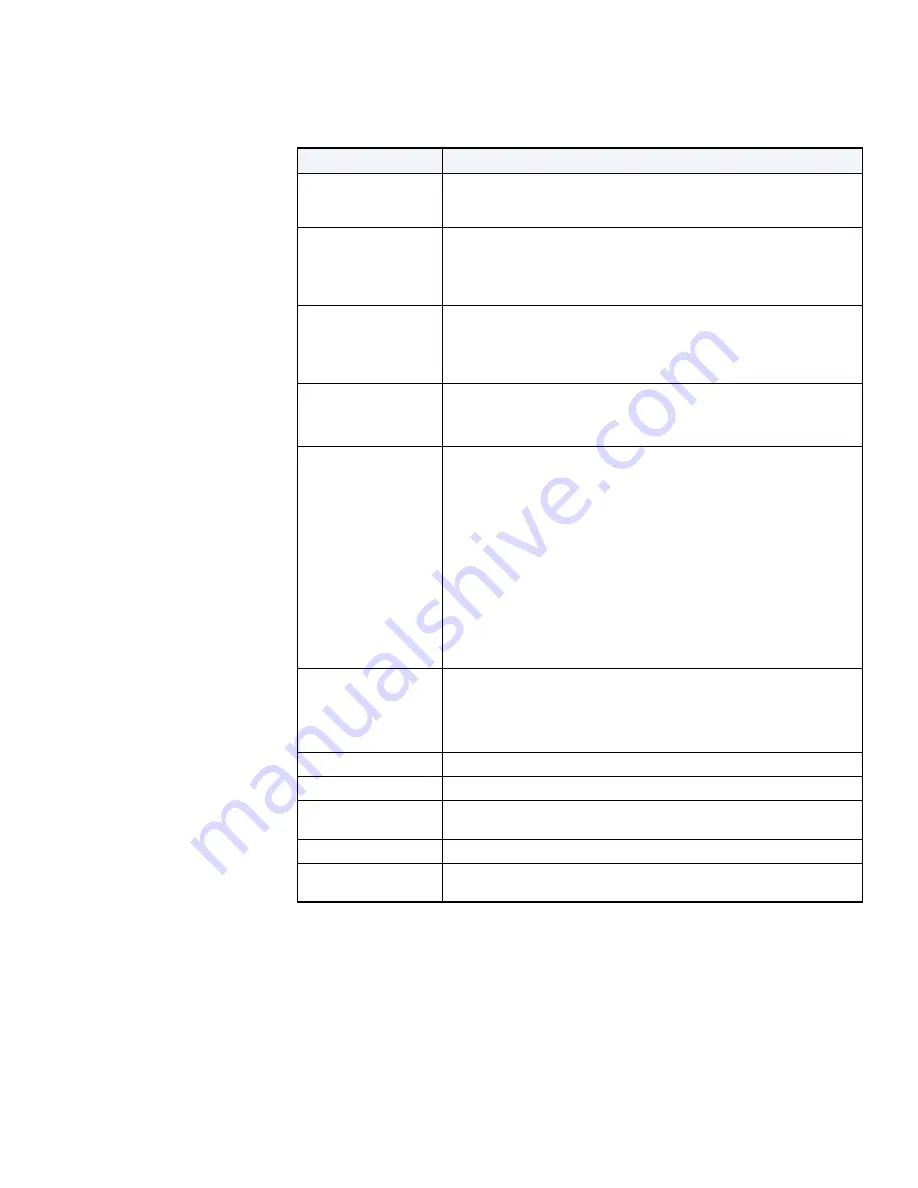

Test Station Software Parameters

ITEM

DETAILS

Location

User adjustable text field that is logged with each test. Used to

assign a unique name to the Test Station. This appears on the test log

file. For example, “Tailer 57 Test Station”.

Number Event Logs

Specifies the number of consecutive monitor event logs to store and

to transfer from monitor to Test Station.

Default= 10

Range= 0 to 500

Auto Power-Off Time After performing a test, the Test Station powers off after 120

seconds. To change, select from the other options.

Default=120seconds

Range=0 to 3600seconds.

Maximum Bump

Time

Maximum time to apply gas if a sensor isn’t responding.

Default=30seconds

Range=20 to 80seconds.

Gas Bottle Fields

Note: Verify the entries and make sure they match the gas bottles in

use. If gas bottles and the mixture change, update the gas

concentrations in these boxes or the tests will be inaccurate.

Allows entering information pertaining to the calibration gas.

Expiration Date and Bottle Lot# appear on each test record. If the

expiration date is set to today’s date, that field remains blank on the

test record.

Note: Changing any of the Testing Check Boxes may disable key

testing functions.

Note: Click on the arrow to access the pull-down calendar and select

a specific date.

Note: Update expiration date, bottle lot and mixture data each time a

new bottle of Calibration Gas is inserted into the Test Station.

Firmware Upgrade

Allows Firmware upgrades during the life of the Test Station. These

may be product improvements to add additional features or to

enhance monitors performance. Most firmware upgrades are not

required unless notified by us. To see if your monitor has the most

current version, please contact us.

Allow Calibrations

Can optionally enable/disable calibrations form the Test Station.

Allow Bump Tests

Can optionally enable/disable bump test form the Test Station.

Allow Hibernate

Can optionally enable/disable 2 button press to hibernate CO and

H

2

S monitors.

Allow Configurations

Can optionally enable/disable re-configuring the monitors.

Allow Firmware

Upgrade

Can optionally allow Monitor firmware upgrades to the image stored

on the Test Station.

Summary of Contents for Protege ZM

Page 1: ...Protege ZM System Guide PROTEGE ZM PORTABLE GAS SYSTEM 087 0048 Rev B ...

Page 2: ......

Page 3: ...Protege ZM System Guide PROTEGE ZM PORTABLE GAS SYSTEM 087 0048 Rev B ...

Page 10: ...X LIST OF TABLES 087 0048 REV B SCOTT SAFETY ...

Page 20: ...XX ABOUT THIS GUIDE 087 0048 REV B SCOTT SAFETY ...

Page 24: ...4 CHAPTER 1 QUICK REFERENCE 087 0048 REV B SCOTT SAFETY ...

Page 30: ...10 CHAPTER 2 INTRODUCTION 087 0048 REV B SCOTT SAFETY ...

Page 44: ...24 CHAPTER 3 INSTALLATION 087 0048 REV B SCOTT SAFETY ...

Page 62: ...42 CHAPTER 4 CONFIGURATION AND SETUP 087 0048 REV B SCOTT SAFETY ...

Page 98: ...78 CHAPTER 6 MAINTENANCE 087 0048 REV B SCOTT SAFETY ...

Page 114: ...94 INDEX 087 0048 REV B SCOTT SAFETY ...

Page 115: ......