80

APPENDIX A: SPECIFICATIONS

087-0048 REV B

SCOTT SAFETY

Specifications

lists the monitor’s specifications.

lists the IR Connect

specifications.

lists the Test Station specifications.

Table 26

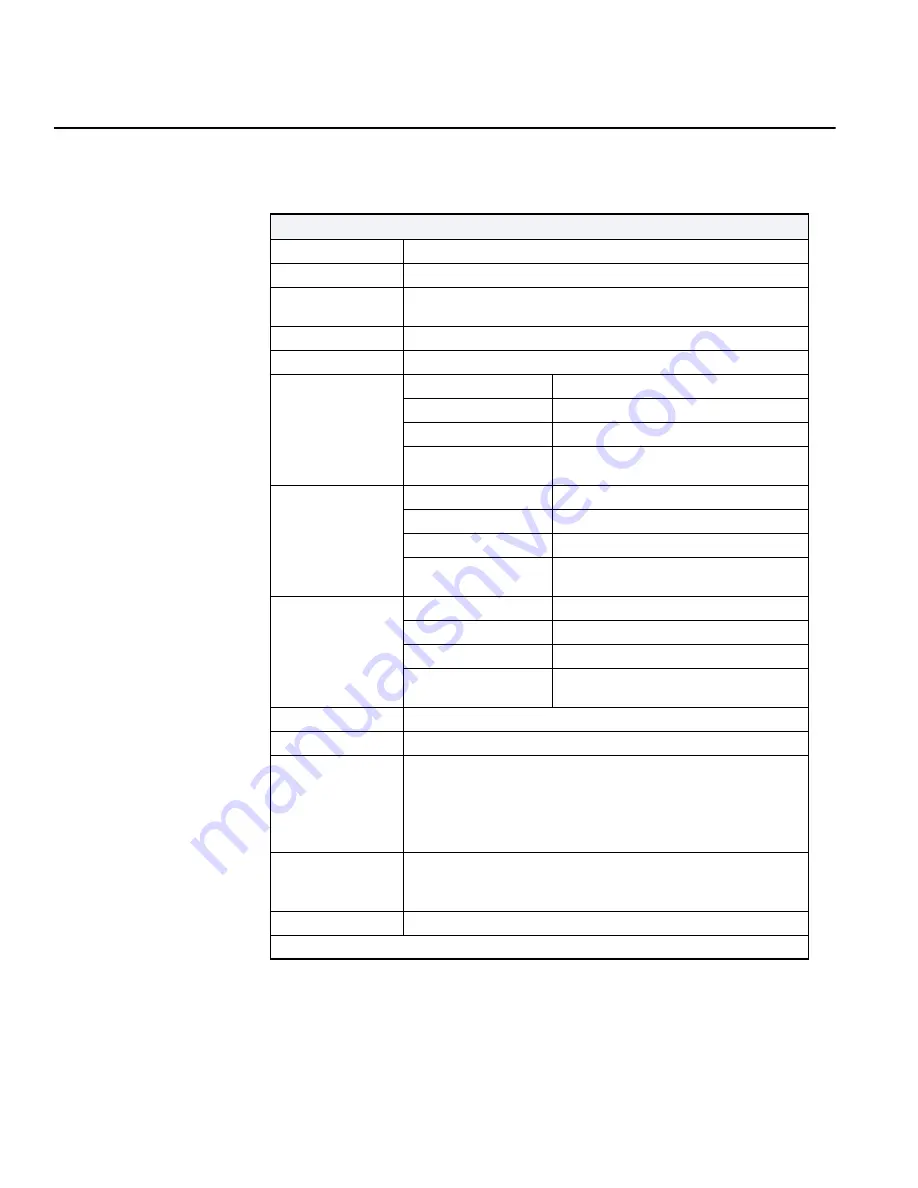

Monitor Specifications

MONITOR SPECIFICATIONS

Battery Life

2 years, 4 minutes of alarm time per day

Alarms

Visual, vibrating, audible 95dB

Tests

Full function self-test on activation and every 20hours;

continuous automatic battery tests

Data Log

Last 25 events

Housing

Impact Adsorbent Overmold

Hydrogen Sulfide

Range

1 to 100PPM, 1PPM

Low Alarm Set Point

10PPM*

High Alarm Set Point

15PPM*

Calibration Gas

Concentration

25PPM

Carbon Monoxide

Range

1 to 300PPM, 1PPM

Low Alarm Set Point

35PPM*

High Alarm Set Point

200PPM*

Calibration Gas

Concentration

100PPM

Oxygen

Range

1 to 30% Volume, 0.1%

Low Alarm Set Point

19.5%*

High Alarm Set Point

23.5%*

Calibration Gas

Concentration

16%

Dimensions

3.7Hx2.2Wx1.3”D (94Hx56Wx33mmD)

Weight

2.7oz (76g)

Intrinsically Safe

Approved

Temperature Range

H

2

S:-40 to +122

°

F (-40 to +50

°

C)

CO:-22 to +122

°

F (-30 to +50

°

C)

O

2

:-58 to +122

°

F (-50 to +50

°

C)

IS approved temperature may not reflect the operating

temperature.

Operating

Temperature Range

H

2

S, CO and O

2

:14 to +122

°

F (-10 to +50

°

C)

For values outside this temperature range, you may experience

reduced performance or alarm functionality.

Operating Humidity 5% to 95% RH, Non-Condensing

*Note: These values are factory defaults. These values may be changed.

Summary of Contents for Protege ZM

Page 1: ...Protege ZM System Guide PROTEGE ZM PORTABLE GAS SYSTEM 087 0048 Rev B ...

Page 2: ......

Page 3: ...Protege ZM System Guide PROTEGE ZM PORTABLE GAS SYSTEM 087 0048 Rev B ...

Page 10: ...X LIST OF TABLES 087 0048 REV B SCOTT SAFETY ...

Page 20: ...XX ABOUT THIS GUIDE 087 0048 REV B SCOTT SAFETY ...

Page 24: ...4 CHAPTER 1 QUICK REFERENCE 087 0048 REV B SCOTT SAFETY ...

Page 30: ...10 CHAPTER 2 INTRODUCTION 087 0048 REV B SCOTT SAFETY ...

Page 44: ...24 CHAPTER 3 INSTALLATION 087 0048 REV B SCOTT SAFETY ...

Page 62: ...42 CHAPTER 4 CONFIGURATION AND SETUP 087 0048 REV B SCOTT SAFETY ...

Page 98: ...78 CHAPTER 6 MAINTENANCE 087 0048 REV B SCOTT SAFETY ...

Page 114: ...94 INDEX 087 0048 REV B SCOTT SAFETY ...

Page 115: ......