Page 6

2.0 SAFETY PRECAUTIONS

1)

The operators of this machine must be qualified and well trained in the operation of the machine.

The operators must be aware of the capacities of the machine and the proper use of the hold down

devices, strippers and guards provided with the machine.

2)

All of the guards, adjustable restrictors and awareness barriers must be installed on the machine

and kept in good working order. Promptly replace worn or damaged parts with authorized parts.

3)

Never place any part of your body into or under any of the machine’s moving parts, strippers or

hold devices.

4)

Wear the appropriate personal protective equipment. Safety glasses are required at all times,

whether operating, setting up or observing this machine in operation. Since heavy pieces of metal

with sharp edges can be processed on this machine, the operator should also wear steel-toed shoes

and tight fitting leather gloves.

5)

Strictly comply with all warning labels and decals on the machine. Never remove any of the

labels. Replace worn or damaged labels promptly.

6)

Always disconnect and lock out the power when performing maintenance work or setting up any

tooling on the machine. Follow the procedures outlined in the operator’s manual for setting up,

changing or aligning any tooling on this machine.

7)

Never operate this machine with dull or damaged tooling. Replace worn punches, dies and blades

promptly.

8)

Practice good housekeeping. Keep the area around the machine clear and well lit. Do not

obstruct the operator’s position by placing anything around the machine that would impede the

operator’s access to the machine.

9)

Never modify this machine in any way without the written permission of the manufacturer.

10)

Never leave this machine running unattended.

11)

Always operate the punch station facing the station, standing. Never operate any of the work

stations from a sitting or kneeling position.

12)

Set up a program of routine inspections and maintenance for this machine. Make all repairs and

adjustments in accordance with the manufacturer’s instructions.

13)

A safety DVD was mailed to you or shipped with the machine. If you did not receive it,

please contact the factory or your local dealer immediately and one will be sent to you at no

charge. If this machine was purchased used, please contact the factory for a safety DVD.

Summary of Contents for 9012-24M

Page 10: ...Page 9 FIGURE 1 ...

Page 12: ...Page 11 FIGURE 2 ...

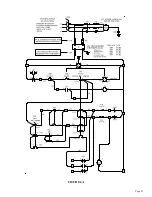

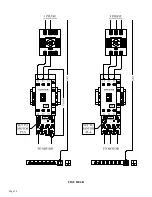

Page 16: ...Page 15 FIGURE 4A ...

Page 17: ...Page 16 FIGURE 4B ...

Page 18: ...Page 17 FIGURE 4C ...

Page 22: ...Page 21 FIGURE 6 ...

Page 24: ...Page 23 FIGURE 7 ...

Page 35: ...Page 34 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 40: ...Page 39 FIGURE 15 ...

Page 42: ...Page 41 FIGURE 16 ...

Page 48: ...Page 47 FIGURE 20 ...

Page 54: ...Page 53 FIGURE 24 ...

Page 56: ...Page 55 FIGURE 25 ...

Page 62: ...Page 61 FIGURE 27 ...

Page 66: ...Page 65 FIGURE 29 ...

Page 68: ...Page 67 FIGURE 30 ...

Page 74: ...Page 73 FIGURE 32 ...

Page 78: ...Page 77 FIGURE 34 ...

Page 80: ...Page 79 FIGURE 35 ...

Page 82: ...Page 81 FIGURE 36 ...

Page 84: ...Page 83 FIGURE 37 ...

Page 86: ...Page 85 FIGURE 38 ...

Page 90: ...Page 89 FIGURE 41 ...

Page 92: ...Page 91 FIGURE 42 ...

Page 93: ...Page 92 FIGURE 43 ...

Page 96: ...Page 95 THIS PAGE LEFT BLANK INTENTIONALLY ...

Page 98: ...Page 97 FIGURE 46 ...

Page 100: ...Page 99 FIGURE 47 ...