NOTE: On transmission input pinion gear oil seals with less than

two hours of operation, some seepage or wetting of adjacent

surfaces is normal until seal is wetted and worn in (seated). If

seepage continues at a rate of one drop per minute or less, seal may

continue in service. Check transmission oil level and observe

seepage rate after every two hours of operation. Shorter inspection

periods may be required if seal leakage appears to be increasing.

7-36. ENGINE OIL LEAKS

Refer to Rolls Royce Operation and Maintenance Manual,

Publication No. 10W2 for definition of permissible engine oil

leakage.

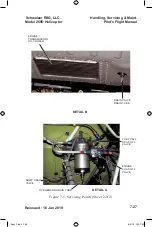

7-37. LANDING GEAR DAMPER - HYDRAULIC FLUID LEAK

NOTE: It is normal for a thin hydraulic oil film to remain on

damper piston as a result of wiping contact with piston seal. Newly

installed dampers may also have slight oil seepage from oil trapped

in end cap threads during assembly. Neither of these should be

considered damper leakage or cause for damper replacement.

Hydraulic fluid leakage from any landing gear damper is not

permissible. If leakage is present, damper assembly should be

removed and serviceable unit installed. If leaking landing gear

damper is not replaced when leakage is noticed, continuation of

damper in service can cause internal damage that may otherwise not

occur. Also, improper operation of damper(s) may cause conditions

conducive to ground resonance.

7-38. OVERRUNNING CLUTCH - OIL LEAKAGE

If oil leakage is noticed at overrunning clutch (sprag clutch),

corrective maintenance (HMI) should be performed before further

flight. Continuation in service with oil leakage may result in failure

of overrunning clutch and/or oil on drive belts.

Handling, Servicing & Maint.

Schweizer RSG, LLC.

Model

269D

Helicopter

Pilot's Flight Manual

7-39

Reissued:

16

Jan 2019

Book 3.indd 201

8/4/19 1:25 PM