Assembly

24

02.00|WDB 99 |en

CAUTION

Risk of injury due to crushing.

• Carefully install the workpiece direct clamping systems.

• Do not put limbs in the gaps between the adaptable

workpiece direct clamping modules or also the base module

and machine.

• Wear protective gloves.

General assembly notes

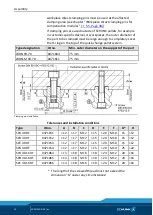

If several clamping pillars with VERO-S NSE plus clamping systems

are mounted linked together, make sure that the interface

position deviation does not exceed ± 0.015 mm.

Due to redundancy between several quick-change pallet systems

VERO-S NSE plus, the clamping pins or the clamping pin extensions

with positioning accuracy in one direction (SPB 40 / SPB-VLK50)

must be used for clamping systems that are more than 160 mm

apart or that do not show a positioning tolerance of ± 0.01 mm.

For the clamping areas that are not intended for alignment of the

device, the workpiece or the pallet, clamping pins or clamping pin

extensions with centering clearance (SPC 40 / SPC-VLK50) or alter-

natively the compensation module WDA 99-70-36 can be used

(also refer to chapter "Clamping pins"

). An indi-

vidual height compensation on the Z-axis can be achieved at the

same time as the longitudinal distance between two shifted

clamping pillars using the compensation module WDA 99-70-36.

NOTE

When connecting the WDB 99-60 base module or the WDG 99-60

basic module or the WDR 99-60 raster module for supplying com-

pressed air to the quick-change pallet system, bear in mind that it

is only possible to completely ventilate the piston chamber via the

air connections during the locking process. The relevant valves or

shut-off valves should therefore be equipped with load relief. This

also applies to the turbo connection. If the turbo connection is not

used, it must be possible to ventilate the relevant side of the pis-

ton. In this case, the pressure ventilation would have to take place

via an open air connection on the WDB 99-60 or WDG 99-60 base

module. The connection may not be closed by a locking screw for

this, as otherwise an air cushion in the quick-change pallet system

would form; this would mean the quick-change pallet system

would no longer be able to be opened.

5.2