Operating Manual

V

ACU

M

ASTER

Multi-Serie

Chapter 7

Maintenance

J. Schmalz GmbH

Aacher Straße 29

D - 72293 Glatten

Tel +49 +7443 / 2403 - 0

Fax +49 +7443 / 2403 - 259

http://www.schmalz.de

e-mail: [email protected]

BA 30.30.01.00221-00

Status 03.2013

Page 16/18

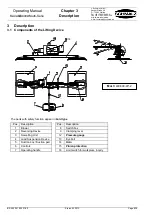

7.4 Adjusting the spring-

pressure brake

(only Multi ...-90°)

Remove the actuator cover M14.

Loosen the actuator clamping screws B14.

Remove the O-Ring B62 and insert shims B40 between the armature

plate B42 and the plate B16 (thickness of shims B40: 0.25 - 0.30 mm).

Tighten screw B31 until the shims can still just be removed.

Tighten the actuator clamping screws B14 uniformly, beginning with the

screw opposite the key slot (tightening torque: 5.5 Nm).

Tighten screw B31 again.

Remove the shims B40.

Install the actuator cover M14.

Test the operation of the brake.

Brake type:

EFB 2

Nominal braking torque: 7.5 Nm

Air gap, max.:

0.6 mm

Adjusting shims:

0.25 - 0.30 mm

Pressure spring color:

black

7.5 Changing the Oil in the

Gearbox of the Swivel

Unit

(only M

ULTI

...-90°)

The oil in the gearbox of the swivel head must be changed after 10,000

operating hours or after three years, whichever occurs sooner. Oil capacity:

0.2 litres. To change the oil, first open and clean the gearbox and check the

condition of all parts subject to wear. Fit new shaft sealing rings.

The specifications apply for operation under normal conditions, at ambient

temperatures in the range -10°C to +40°C.

Recommended oil: Aral Degol BMB 680. At temperatures in the range -10°C

to -20°C, use Degol BMB 220+, at temperatures below -20°C BMB 46+.

Equivalent oil types:

Aral

Degol BMB 220

BP Energol GR-xP 220

Calypsol

Bison Oel MSR 114

ESSO

Spartan EP-220

Houghton Molygear 115

Mobil

Mobilgear 630

Shell

Omala 220

Before assembly, clean the housing gaskets and apply a plastic sealing

compound (such as Dirko).

Refill the gearbox. Never mix mineral and synthetic oils.

7.6 Vacuum blower

See operating manual in appendix.

7.7 Suction Pads / Seals

Warning

Remove items and contaminations such as adhesives, glue, saw dust, dust

etc. sticking to the seals at least once a week. Use glycerine to clean the

seals.

Immediately replace damaged seals (tears, holes, waves).