www.scheppach.com

+(49)-08223-4002-99

+(49)-08223-4002-58

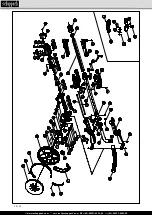

19 І 32

www.scheppach.com

+(49)-08223-4002-99

+(49)-08223-4002-58

side but is removed by the extraction system. Make

sure before each operation with this power tool that

the brush edge (10) is not damaged. Have it replaced

if there is damage or wear.

Connection to the power supply

1. Make sure that the power tool is switched off. Always

switch the on/off switch (3) to off position before con

-

necting the power tool to the power supply.

2. Plug the power plug into a correctly installed socket

which camplies with the requirements specified in the

technical data.

3. Your power tool is now ready for operation.

Operation

Oscillation rate

Before you start working with the swing speed to match

the appliance. Use a low swing speed for coarse grind-

ing, increase the oscillation rate for fine work.

1. Rotate the adjustment wheel (6) to adjust the oscilla-

tion rate. Turn the wheel clockwise to reduce the os-

cillation rate (Fig.9).

2. Turn the wheel counter-clockwise to increase the os-

cillation rate (Fig. 10).

Switching on/off

To switch on:

Push the on/ off switch (3)

Continuous operation: (Fig.11)

Secure the on/off switch (3) with the Ieeking button (a)

To switch off:

Press the on/off switch (3) briefly.

Note:

The insertion tool moves for a short while after

having it switched off. Do not put aside the power tool

until the insertion tool has come to a complete halt.

Grinding

1. Attach an appropriate abrasive sheet (13) and select

the corresponding speed.

2. Hold the power tool securely at the handle surfaces

(1, 2) and switch it on as described.

3. Wait until the insertion tool has reached its full operat

-

ing speed.

4. Hold the grinding plate (9) as parallelas possible to

the wall, and touch the surface tobe processed with

the brush edge (10) first.

5. Apply some pressure to the grinding head (8) such that

the insertion tool touches the surface to be processed.

6. Constantly move the power tool over the surface.

Note:

lf you want to avoid irregular grinding results, do

not keep the power tool at one spot for too long.

7. Lift the grinding plate (9) from the surface to be pro-

cessed before switching off the power tool.

8. Do not put aside the power tool until the insertion tool

has come to a complete halt.

Sandpaper

Selection

1. The grain size of the sandpaper is specified on its rear

side. The smaller the specified number, the coarser

the graining.

2. Use sandpaper with coarse grain for rough grinding,

and sandpaper with fine grain for finishing. We re

-

cornrnend sandpapers with aluminium oxide, silicon

carbide or other synthetic abrasives.

3. lf you can chose between sandpapers with different

graining, you should start with coarsegraining sandpa-

per and complete the grinding process with the finest

possible graining. Thus you will get good and smooth

grinding results.

How to apply and replace sandpaper

Apply the sandpaper (13) to the grinding plate (9) using

the Velcro strip mechanism.

1. Align the sandpaper (13) with the grinding plate (9)

and press it on evenly.

2. PuII the sandpaper (13) off the grinding plate (9) and

replace it with a new one I another one (Fig.5).

Dust extraction

WARNING! Harmfull noxious gases may be generated

when e.g. lead-containing paint is processed. These

gases entail a risk for the operator and the persons in

the vicinity!

Therefore only use the power tool in combination with

a dust extraction unit, and protect yourself and other

persons in the working area with additional suitable per-

sonal protective equipment!

When working with this power tool, a Iot of dust is gener-

ated. The dust extraction unit is very useful if you want

to keep your workplace clean. lt is possible to combine

the extraction system or a vacuum cleaner with the ex-

traction hose (11) which is connected to the adapter for

dust extraction.

1. Align the nose at the hoseend with the extraction hose

adapter (12) (Fig.3), insert the end and secure it by

turning in a clockwise rotation (Fig.7).

2. Connect the dust extraction adapter with a suitable

dust extraction unit such as a vacuum cleaner (Fig.8).

Note:

Make sure that the vacuum cleaner is suitable for

being used tagether with a power tool.

Brush edge

The grinding head of this power tool is enclosed by a brush

edge (1 0) which offers the following two advantages:

a) The brush edge (1 0) protrudes beyond the grinding

plate (9) and touches the surface to be processed

first. Thus, the grinding plate is positioned in parallel

to the working area before the insertion tool comes in

contact with the surface which is to be processed. This

is to prevent the formation of sickle-shaped recesses

caused by the grinding disk edge.

b) Furthermore, the brush edge (10) prevents the gen-

eration of excessive dust. Dust generated du ring the

grinding process is not transported towards the out-